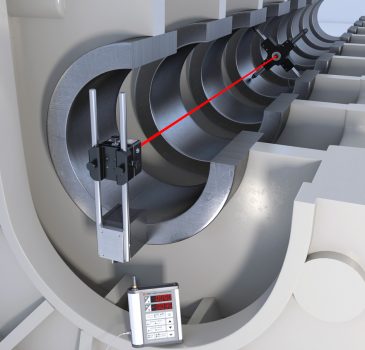

Our 55 years of alignment experience went into the design of the L-703 Self-Centering Bore Alignment System that makes aligning engine blocks easier and faster:

- Replacing our workhorse bore laser, the L-706, the newly designed L-703B Laser is smaller and lighter than previous models.

- Also newly the designed L-103 Laser Beam Translator (replaces the L-102) and L-112 Laser Stand (replaces the L-111), are used to hold the laser externally but on center to the bores.

- Easy-to-use, patented self-centering targets that only require 1 measurement per bore — no 0° and 180° measurements!

- Setup in as little as 15 minutes; bore alignment data can often be analyzed in 30 minutes or less.

- Our self-centering targets can easily measure bore diameters from 1.18 to 40 in. (30 to 1,000 mm).

- Resolution of .00004 in. (0.001 mm) and bore alignment/concentricity accuracy up to .0002 in. (0.005 mm) per 10 feet (3 m).

- Simple X-Y readouts require very little training, making it the easiest system on the market to learn and use.

- L-703B runs on a lithium-ion, rechargeable battery with 11 hours of continuous battery life.

- Optional Windows-based Bore9 Software records data, analyzes the results and produces reports.