Hamar’s L-743: The Best Alignment Tool, Period

Most of my 20 years of professional machine tool experience includes rebuilds, relocations and retrofits of very large machines that need extremely precise alignment and calibration, and I am familiar with many kinds of alignment tools. I have successfully used Hamar Laser’s L-743 [Ultra-Precision Triple Scan® Laser Alignment System] on almost every one of these projects. I believe Hamar’s L-743 is the best alignment tool on the market and really the only solution for proper alignment of large machine tools.

I was Vice President of Engineering at Team Machine Tools in Mississauga [Ontario, Canada] for 15 years, then retired and founded Vital Machine Tools and Automation in Richmond Hill in 2016. I provide my customers with expert consulting in virtually every aspect of machine tool and automation services, including retrofit, upgrade, alignment, calibration, and troubleshooting. At Team Machine Tools, we used Hamar Laser’s L-743 for 80 percent of our machine relocation projects and machine condition checks and realignments. I fell in love with the L-743 the first time I saw it in action at a customer’s place in Pennsylvania. Now I use only the L-743 in my work.

This tool perfectly covers all machine geometry alignment and check tasks: leveling, parallelism, straightness, flatness, and squareness. Hamar’s L-743 is the only alignment tool I have seen that has three auto-rotating and square laser planes. So, when you’re setting up the laser on these big machines, 90 percent of the time you can set up in one place and then do all the checks and alignments to the machine without having to move any equipment. When relocation is necessary, this is very quick and easy. I think this is the most important difference compared to other alignment tools.

There are other differences, too. Technology is moving ahead today, and we have new equipment on the market which can do alignments, but not as well as Hamar tools. Laser interferometers are sensitive to laser beam breakage. If something accidentally crosses the laser beam you need to start the checks all over again. And we have laser trackers, but I did not have a good experience with them. Yes, some new tools may do a fair job, but they are much more expensive and complicated. You need special knowledge and skill, and the software is harder to use. Hamar systems are very user friendly, and the software tells you exactly what is going on. You can see the alignment data right away and make adjustments in real time.

Over the years I have managed projects for many large machine types using Hamar Laser’s L-743. These range from machines like Toshiba’s floor-type horizontal milling and boring machine to very large machines like a Dorries 13.2m vertical turning lathe – one of the largest machines in North America, and an Ingersoll 15m gantry-type milling machine. The larger the machine tool, the greater the advantages of using the L-743.

The way we align all these machines is very similar. We set the machine base on the foundation, set square and parallel between major components, assemble the machine and then do the full calibration. The L-743 always performs all these tasks much more easily and much faster than any other equipment I have used. In every case, Hamar’s L-743 let me complete these jobs very effectively and efficiently to the customer’s complete satisfaction.

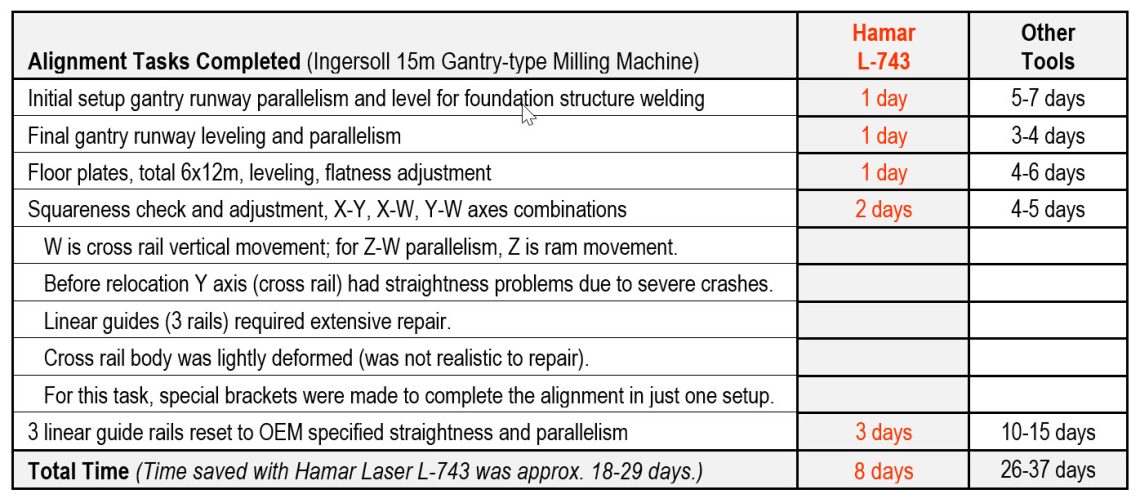

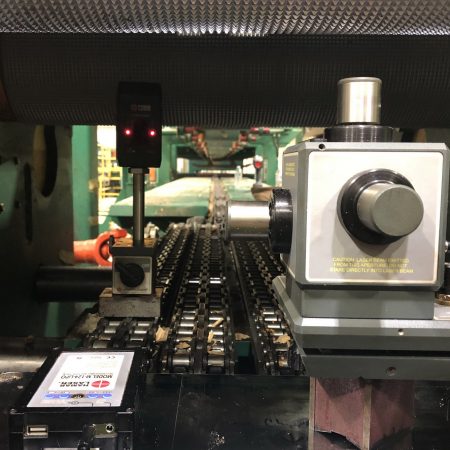

The large Ingersoll machine relocation job was one of the best examples. The gantry runways were 15m with actual machine stroke 10m, and inside distance between columns 8m. The cross rail was the CNC axis. My partner worked with me, and the job was so critical we had to avoid making any mistakes. The L-743 allowed us to complete all tasks in record-breaking time. [See table, below.] Using conventional and other laser equipment we would have needed from four to seven times more time. Gantry runway parallelism especially would have required much greater time, and we would have needed to design and make some expensive fixtures. We purchased the Hamar laser just before starting the project, and it was mostly paid off by the time we completed the job.

Hamar Laser’s L-743 has been my tool of choice on the many machine tool projects I have successfully completed, and this includes very large machines for which there is no better alignment tool, period. The laser’s clever design was invented by Martin Hamar years ago and is still the best tool for machine alignment. It was a very good design then, and still is. But that’s Hamar Laser – there’s just no other brand name like this one.

Ingersoll Large Gantry-type Milling Machine

L-743 Laser Outshines Optics in Sawmill Alignments

I’ve got to say Hamar Laser’s L-743 [Ultra-Precision Triple Scan® Laser] is a fantastic tool. It’s fast, it’s accurate. It’s very portable. To do the same amount of three-axis work as the L-743, I’d have to carry three optical scopes with me, which is just not possible.

I started SawPro in 1996 after working in a couple of local sawmills for about 20 years. My work included developing the first variable-tooth pitch and depth band saw blades in our industry in the early ’90s. Today SawPro specializes in developing and training saw filing staff and troubleshooting sawing issues, and we analyze, repair and align machine centers to maximize productivity for customers on four continents and across the U.S.

Always looking to improve efficiency, I began looking into lasers. Because of errors from dust and heat that I saw in some lasers, I shied away from using them until I ran across a Hamar in the field. A service outfit with an L-743 and I were both hired to do similar jobs in the same sawmill, and this let me compare the laser with my Brunson [76-RH Telescopic Transit Square].

The tech with the Hamar L-743 was shooting the feed system and I was shooting the supporting band mill and aligning the band mills and guides. I was really impressed with the incredible accuracy he was getting and that his measurements were very repeatable. What also impressed me was that the L-743 measured in three axes, whereas I had to move my Brunson from one axis to another and buck-in again.

To me, Hamar’s L-743 was like three alignment tools in one and I didn’t have to move out of position at any time. Therefore, the laser was easily three times faster, if not more, than the optical equipment I had been very satisfied with, and so I switched to the L-743. That was many years ago and I’ve had really great success with it ever since.

Recently, I did a head-rig track alignment job for a large sawmill. We had to break 60 feet of track loose, with both flat and “V” rails. This would’ve taken three days with the Brunson but the Hamar let me run two teams. We were within .005 inch in 60 feet, in plumb, level and straight, and were done in only a day and a half. The sawmill, which had struggled with the machine center for a year and a half, almost doubled production. Like many jobs I’ve done with the L-743, this one turned out just fantastic.

Hamar Trounces Competitor in Engine Bore App

My company, Cleveland Brothers Equipment Co., Inc., is a CAT® dealer providing equipment sales, rentals, parts and service. We pride ourselves on providing a one-stop shop with a strong customer service focus. We recently purchased the L-706 [Bore Laser System] from Hamar Laser Instruments. It’s a fine tool for engine block bores, is extremely repeatable and much faster than other tools we’ve used.

In the Engine Rebuild Center where I work, we tear down and rebuild engines, mainly those used in gas compressor stations. We’re using the Hamar L-706 to check main bore alignment on CAT G3500- and G3600-series engine blocks. These are bigger engines, ranging from 10 to 12 feet in length and can have as many as 11 bores.

We had been using a competing European company’s alignment tool, but we weren’t at all happy with the repeatability. We fought with it from the start and just couldn’t seem to get it to repeat, even when we were confident in what we were measuring. In comparison, the L-706 is simple and easy to use and has great repeatability. It doesn’t take long to set up and the [Bore9] software speeds up the buck-in (laser setup) process and data taking.

We’re super happy with the Hamar’s repeatability, which gives us a lot of confidence. This has been one of the biggest gains for us, since we don’t have to go back through and check the alignment several times to see if we can get acceptable repeatability. I have a machinist background, but I also have quite a few years in Quality Control, so to me, repeatability is everything.

Now with our Hamar, checking the bores takes a fraction of the time it used to. What took half a day with the other tool takes only an hour with the Hamar, which is about 75% faster with the L-706. Time is of the essence here because we’re up against a tight timeframe to roll the block through and get the engine back to the customer.

The Hamar has it all—a fast and easy setup, fantastic repeatability and lots of time saved. We’re very, very happy with this great alignment tool, and the customer service is great, too. I can highly recommend Hamar Laser and the L-706.

L-706 Bore Laser System in CAT 3600 engine block bore application

S-680 Stars in PM Role

I founded Condition Monitoring Services in 2005. Originally focused on vibration analysis services, we grew quickly and are now a true reliability resource company offering full-service Predictive Maintenance support but without being tied to specific services or products. We brought in Hamar Laser because they are a highly reputable American company with a superb five-axis laser shaft alignment system. Hamar is by far one of the best vendors we have worked with and the Stealth Series S-680* is the best shaft alignment product we have ever used.

One of the things we like best about the S-680* is that you can leave the heads in one position and perform the vertical and horizontal corrections simultaneously with live values. At first I was skeptical you could do this. My first alignment with the S-680* was at a solar generating facility—3,600 rpm heat transfer fluid pumps driven by 600 or 800 hp motors—high speed, high tolerances. I made my vertical and horizontal corrections leaving the heads in one position and brought the system into alignment. Then I actually removed and remounted the heads just to double-check because I did not believe I could do it in one move. The next job was a boiler feed-water pump system at a power plant. Again, when I repeated the alignment the results were the same. This made a believer out of me!

The S-680* is not only easy-to-use, it’s extremely accurate. Other things we like are that it uses a rugged tablet PC with Bluetooth capability. If you break a screen or have a problem with the tablet, you don’t have to buy a whole new system. The easy-to-use Couple6 software guides you through alignments. Sticklers for accuracy, Hamar designed the S-680* with hardware and software features that ensure the highest accuracy in all ambient lighting conditions.

Alignment is a key factor in a good reliability program and Hamar’s S-680* helps us generate a quick return-on-investment for our customers. When we start a program, we often see customers experiencing repeat part failures from misalignment. After alignment, failure rates go down dramatically. Power costs go down, too, because misaligned machinery draws more current. This is a kind of “double jeopardy” because that extra current not only costs more but tears up the equipment. So the S-680* saves money by reducing failure rates and related downtime expenses, as well as lowering power costs and extending equipment life. Accurate laser alignment truly pays for itself very quickly and helps us keep customers happy!

[For information on Hamar Laser’s shaft alignment products, visit shaftalignment.hamarlaser.com.]

S-680: Best Shaft System Ever!

I have been a field vibration analyst with Condition Monitoring Services since 2013. CMS is a reliability resource company that provides full-service Predictive Maintenance support. In my more than 15 years in the field, I have seen and used lots of alignment equipment. The S-680* from Hamar Laser is the best shaft alignment system I have ever used, and I have used it to align everything from extremely small pumps to large pumps for power plants, as well as in mills and mines.

There’s a lot I like about Hamar’s S-680* compared to other systems: First, you can leave the heads in one position and make the vertical and horizontal moves, a big time-saving feature. It’s extremely accurate, transmits alignment data wirelessly using Bluetooth and has a very intuitive, easy-to-use software package [Couple6]. It incorporates ambient lighting correction and has a sun filter that’s great for outdoor jobs. I can pop the filter on and not have any issues with light sources interfering with accuracy. That filter has saved me a lot of grief! Also, it uses a PC tablet instead of a dedicated display so if you have a problem with the tablet you don’t need a whole new system.

The S-680* makes us shine as reliability pros. Our new customers are often experiencing high failure rates due to misaligned equipment, but they see those go down significantly after starting a PM program with us. For example, a gypsum plant in Las Vegas was seeing continual failures on their mills, often due to losing bearings, even on the larger 300 hp units. They used to call us for alignments after failures two times per quarter. After we began aligning their equipment and getting it set up properly, that fell to two calls per year―roughly a 75%-reduction.

Another good example: A gold mine in Laughlin, Nevada had been running a very small, high-speed pump that was essential for their processing operation. The unit had a coupling failure about once every three to five weeks. After we corrected a number of issues with the pump and got it aligned properly, the last coupler has been running well for 18 months.

Compared to other companies, the service behind the product is superior. Hamar Laser’s customer support people are always extremely helpful with any operator issues, and their field sales reps are very supportive. We’ve been very happy with Hamar Laser and the S-680*!

[For information on Hamar Laser’s shaft alignment products, visit shaftalignment.hamarlaser.com/.]

L-702SP Streamlines Bearing Bore Reconditioning

Hi-Tech Compressor and Pump reconditions bearing bores in large compressors with either thermal spray or sleeves (both processes are done in house), and we re-machine them to a close-tolerance diameter. Regardless of the recondition method used, the challenge is to maintain tight OEM tolerances on concentricity and perpendicularity to a reference bore. Our previous method of setup was to tram the housing to the horizontal boring mill spindle using dial indicators. This process was time consuming, plus it was hit-or-miss as to maintaining required tolerances. Also, we lacked an accurate method of final inspection to measure and verify the finished bores.

I reached out to Hamar Laser and scheduled an on-site visit and demo of their alignment equipment with Rod Hamar. In preparation for his visit Rod helped me design a fixture to locate Hamar’s L-702SP [Scan Laser with Plumb Beam] to the reference bore. We were very impressed and purchased the alignment system based on the success of the demo.

Using Hamar’s system each housing is now individually aligned to the spindle of our horizontal boring mill in a simple 3-step process: (1) Using the scan plane of the L-702SP laser and the A-1519 target, the laser is adjusted perpendicular to the reference bore. (2) The laser beam is then adjusted to the center of the reference bore with the A-512 target. (3) Now that we have an accurate reference, a beam which is both perpendicular and concentric with the reference bore, the T-261A 4-Axis spindle target is mounted in the spindle. The target, along with Hamar’s system software, is used to square the part with the machine and adjust the spindle to the part centerline within tenths. Finally, a finished inspection is performed repeating steps 1 and 2 above but using the A-514B target adapter (and the A-512 target) to qualify and record the finished bore location.

We shaved a significant amount of time out of our alignment process with Hamar’s system and gained the confidence that we are able to consistently hold the required tolerances. Most important, however, is the confidence and increased business from our customer!

[Read the case study on this application in our Resource Center (click Case Studies tab). The case study was published in CompressorTECH2, a leading trade magazine. Step-by-step alignment procedures for the application are available as a downloadable PDF.]

Aligning compressor bearing bores with Hamar Laser’s L-702SP Scan Laser with Plumb Beam

Hamar’s L-743: A Great Tool for Sawmills!

Idaho Forest Group (IFG) is a family-owned lumber producer based out of Coeur d’Alene, Idaho. I am the head filer in the Grangeville mill, one of six sawmills IFG owns and operates in Idaho and Montana. The mill recently got the Hamar Laser L-743 Ultra-Precision Triple Scan Laser and we’ve been using it to align our sharp chain machine center and curve gang line. It’s been working very well, and there are a lot of things we really like about it already.

When we do alignments here, the filers work with the maintenance team and the optimization technicians. All the team members involved really like the repeatability and simplicity of the L-743. It’s a great tool for sawmills! It has 3 automatically sweeping laser planes, so we can set up the laser just once in the center of the machine and get data for elevations on bed chains, anvils and scan chains. We can also check the spike rolls, chipping heads, vertical anvils and bandsaws to our center line in the machine centers. This used to take many more setups and a lot more time using optics. Also, we really like the R-1308 digital readout because we can make adjustments in real time. We’ve been extremely happy with the L-743 and will be using it to align the other machine centers and the planer in the near future.

L-742 Streamlines CMM Alignments

Borbolla Metrology has been using Hamar Laser’s L-742 Ultra-Precision Dual Scan Laser to align Coordinate-Measuring Machines (CMMs) and other machines for many years. The L-742’s 2 automatically sweeping, perpendicular laser planes has performed very well in the field. The laser is highly accurate and easy to use and lets us perform machine alignments more quickly. The L-742 sets up easily and gives us alignment data extremely fast and in real time. We do not see these qualities in other alignment tools.

Our company is a distributor of measurement equipment, specializing in dimensional metrology, and sells and services CMMs. We started in 1996 in order to offer these services with a high degree of professionalism and customer service. We have worked with Hamar Laser from the beginning because they share our commitment to delivering superior service. The company is always very responsive to our needs and is extremely quick to resolve any issues.

CMMs measure objects’ geometry by sensing discrete points on their surface with probes. We recently used Hamar Laser’s L-742 to align a Wenzel RS-1618. The RS-series are horizontal arm CMMs used for measurement of vehicle components, assemblies and other large parts. We use the L-742 system to level and make the table flat when the table is cast iron, and to rough-square the machine mechanically. Because it is so easy to set up and gives us data so quickly, the L-742 saves us a lot of time when setting up or servicing CMMs. The L-742 saved us four hours, for example, when we aligned the RS-1618.

Hamar Laser has been a trusted supplier for us for more than 25 years. Our customers and machine manufacturers, such as Wenzel, really like Hamar Laser’s technology. We think anyone that needs highly accurate and very easy-to-use alignment systems, and who wants very responsive customer service, should consider working with Hamar Laser.

Hamar Laser’s L-742 being used to align a Wenzel RS-series CMM

L-743 Cuts Bridge Mill Install Time by 2-3 Days!

I want to give you some feedback on our first alignment with our new Hamar system [L-743 Ultra-Precision Triple Scan laser]. We used it to install and align a new bridge mill. It worked better than we expected and was so much easier than the levels [and granite squares] we’ve been using in the past. We leveled and squared the bridge mill with the L-743 in 1.5 days instead of the 4-5 days it would have taken using our old equipment! Based on this time savings, we think we will get a payback in 9-12 months!

Sawmill Customer Praises the L-733

Our new L-733 Precision Triple Scan® Laser has been working great in the saw mill where I work. So far we have used it to fix a couple of issues that have plagued our machine for years. I love it!

Our main application is to align machine centers. We have two Chip-n-Saw lines, one large and one small. We also have two edgers. Our alignment consists of making sure our machine line is level, straight (in-line) and square to itself within .005”.

On our small Chip-n-Saw line we had an issue that we thought was due to the outfeed line bar being installed at too high of an elevation compared to the infeed line bar and profile rolls. With the laser we found the infeed line and profile rolls were dropping in elevation, so by the time we reached the outfeed line bar we were running into it. We also found our profile roll box was out of square, which made it impossible to set both rolls square to our feed.

I like that the L-733 lets us shoot straight, elevation and square measurements in just one or two steps, and that it gives us real-time numbers. This is extremely helpful when having to move something back in line. I also like your R-1308 plug-in digital readout that attaches to the target for taking measurements, especially when we are moving something, because there is no delay. I can see the data right away.

I had a couple of questions with the PDA, but your customer support team got me lined out on how to work it. There is a bit of a learning curve for some of our millwrights but the laser is easy to use and they are coming around fast. Overall the laser is a really great tool. If I have any issues, I will contact you and your team. Thank you!

L-743 Leveling Sawmills Log Rollers

L-740 Excels at Hydro Facility

I’m currently a site manager who has been working at hydroelectric facilities in the U.S. Our team uses Hamar Laser Instruments’ L-740 Ultra-Precision Leveling Laser for checking level and flatness on large components, including rotors, stators, imbeds and turbine components such as head covers and facing plates. We also use it for in-situ machining, and checking our “as found” flatness measurements. Based on about 15 years’ experience with it, I can tell you that the L-740 is the best tool out there for leveling applications like these.

We use a variety of measuring tools at our facility, but your L-740 is my guys’ “go-to” favorite for these applications. Compared to our optics kits, the L-740 is much faster and easier to use, and more importantly for me, easy to teach. I have much more confidence that I can send out a tech with the L-740 and know the job will get done fast and done right. Unless a technician is really experienced at optics, it can take a lot more time for him to set it up and finish the job. I also really like the L-740’s built-in, easy-to-read, high-accuracy level vials that make it simple for less-well-trained guys to use without a lot of trial and error.

Then there’s the accuracy. We work with a lot of large surfaces (30+ feet), so having that added accuracy makes the measurement more repeatable and our confidence in the numbers higher. [Ed. Note: Accuracy is .00003 in/ft.] We’ve been very happy with Hamar Laser and your L-740 leveling laser is an especially important weapon in our arsenal. It’s been a great investment and I’m sure that we’ll be using it for at least another 15+ years!

We have used the system now, and it really is good. We used it on an old (circa 1950) crusher motor (200 hp 550 RPM) with a horrible motor base. It helped us get through the massive soft foot issues reasonably quickly, and the alignment was a breeze once we were done with that. The controls were simple and intuitive, and the touch screen made data entry very quick. The constant updates while we moved the motor made the adjustments very easy. The Bluetooth was also very convenient. It was something we initially thought wasn’t necessary, but with large motors it was very nice to be able to walk around with the PDA. It had very good range too. We finished with the motor aligned within very tight tolerances. Overall, I am very happy with the system. I was able to pick it up, and align a motor accurately the first time, with very little training and no previous alignment experience. Thank you for making such an easy to use and accurate system.

The machine move stage is the most critical step in any alignment. Behind its great graphics, this is where we have seen the very high resolution and accuracy of the system pay real dividends, because the live move data on a Stealth* system has proven to be dependable and accurate like never before. I have been very impressed to be able to align a new motor to close tolerances on several occasions with only one alignment measurement, one combined vertical and horizontal live-move correction and a confirmation retest – job done!

The payback is pretty high using laser alignment techniques. Based on my customers’ results, they see that better recovery and other benefits can make precision alignment pay for itself very quickly. Most sawmills have accepted lasers. Laser alignment works so well, we don’t have to convince anyone anymore. The sawmills just call us up now, and we have been very busy!

We’ve been using a Hamar Laser alignment system for 15 years. When anybody sees it in action, they see how accurate it is, how it shows alignment data in real time and how easily the results can be repeated. After that, well, the skeptics become believers.

We have been using Hamar laser equipment for about 14 years and have had nothing but great support from your staff all around, from your receptionist to those doing sales and service. Last year, Craig in your service department worked closely with us to adapt a 1308 readout to use a heavier duty plug vs the smaller standard plug used to connect with one of the A1519 sensors. Your ability to work with us to customize our equipment was much appreciated, and a testament to your willingness to listen to the needs of your end user. Our turbine alignment business depends on our gear being both accurate and dependable, and Hamar Laser delivers on both fronts. Without the equipment you manufacture and your customer support, it would be much harder for me to run my business. Thanks for your continued support.

L-706 Steam Turbine Laser

Just a note to let you know, we completed alignment of the Mazak Slant bed lathe shortly after you and Guy finished your visit with us. We found the head was out of parallel with the bed along with level and twist in the bed. Using your system we were able to re-level and adjust the machine to accuracies within tenths regardless of position through the length of travel. This is the beginning I was sure we could get to and I appreciate your help in getting there. Now I have to drive this program to a consistent level. This helps greatly. Thanks again!

I am very impressed with the overall fit and finish of everything. The Kaisen foam is well designed and every component has a well thought out home. The position and orientation of each component was done in such a way to provide maximum protection of the important pieces. The canvas bags that the stand accessories come in are a very nice touch. The stand components and the methods used for assembly are very high quality. Quality you can feel and see. The tablet preloaded with the training videos which are organized into logical albums will also be extremely handy in the field. The selection of the tablet model and the supplied case are a very attractive pairing. The case is one of the best quality industrial units I have felt. The neck strap is also super handy for the intended use. Finally, the training session was also a very positive experience. Spending time with Darel was not only valuable for the equipment use training but also for his wealth of knowledge and years of experience in the alignment field. We are confident that we teamed with the right group and are very excited to start “Aligning with the best!”

In late 2010 our company received an order to develop a system that would make precise measurements of inner diameter and non-linearity of refurbished oil rig pipes. The idea was to combine several measuring sensors (diameter, non-linearity, inclinometer, rangefinder) in one autonomous wireless probe. The first challenge was to find manufacturers who were willing to work with OEMs. The second challenge was to find an alignment system. Thus there are many different systems on the market. We could only find one that claimed to have suitable accuracy with proper sensor size and that was the L-706 system from Hamar Laser. Mr. Rod Hamar gladly agreed to customize system circuitry to fit in our probe. While working on the project we faced several programming problems. Those were solved fast by Hamar Laser support, and several microprogram changes were made to match our protocols. The system proved to be reliable, robust and even more accurate then we needed. “Proudly made in the USA” exactly describes Hamar Laser.

Pipe probe uses L-706 Laser as reference

We adopted the use of the Hamar Laser alignment system in 2005 and have not looked back since. With its high accuracy and easy-to-use design, our machines’ performance has improved tremendously. Your alignment system allowed our machines to run much faster than their design speeds and to produce finer copper foil more reliably. With this experience, we have started to equip our other sister plants around the world.

The ROI on our Hamar Laser L-742 [Roll Alignment System] alignment system was only 3 months! Thanks for a top-shelf “rubber meets the road” solution!

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser