Description

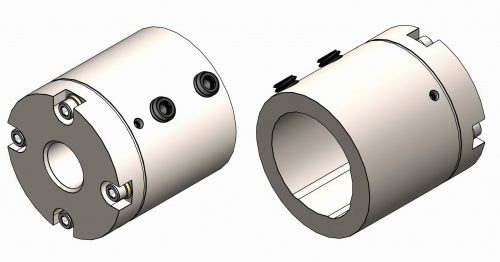

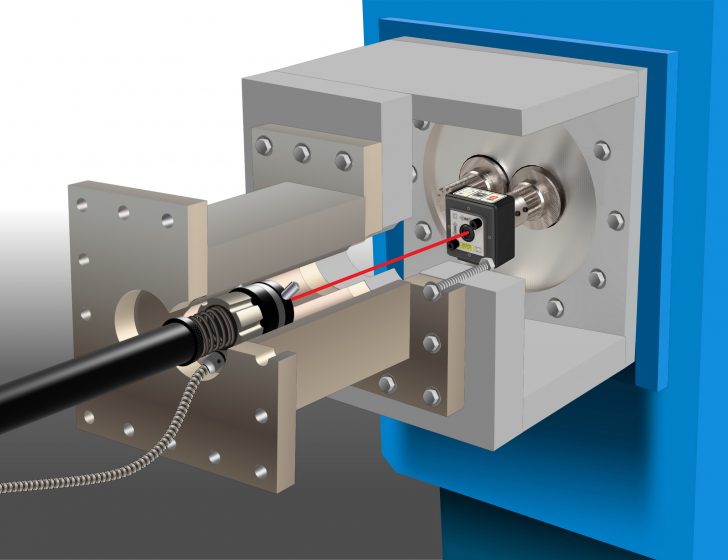

The A-703T is a customized fixture to hold the L-703 Bore Laser on the end of a spline shaft for twin-barrel extruders, so it can be used to check the barrel for alignment in tight spaces. All you need is about 3.25 in. (82.6 mm) of space from the end of the shaft to the barrel.

The A-703T is a customized fixture to hold the L-703 Bore Laser on the end of a spline shaft for twin-barrel extruders, so it can be used to check the barrel for alignment in tight spaces. All you need is about 3.25 in. (82.6 mm) of space from the end of the shaft to the barrel.

It features an adjustable mounting plate that can be used with a dial indicator to align the mounting hole to the rotation axis. It is designed with a slightly larger inside diameter to accommodate the somewhat loose OD tolerances for the shafts and opposing set screws to hold it securely in place.

Applications

- Shaft to bore alignment

- Twin-barrel extruders

Features

- Customized fixture to fit a given shaft OD to hold the L-703 Bore Laser.

- Requires only 3.25 in. (82.6 mm) of space from the end of the shaft to the barrel.

- Also supports the L-700 and L-702SP Lasers.

- Steel adjustable mounting plate that can be used with an indicator to center the hole to the shaft rotation axis.

- Accommodates up to ±.020 (0.5 mm) shaft diameter change from the nominal.

- The mounting plate can be adjusted with the laser installed for very accurate center alignment to the rotation axis.

- Use A-705A Adjustable Chuck for twin-barrel extruder applications that have more axial space and multiple shaft diameters. The A-705A handles a range of shaft diameters from .87 to 2.72 in. (22 to 69 mm).

Specifications

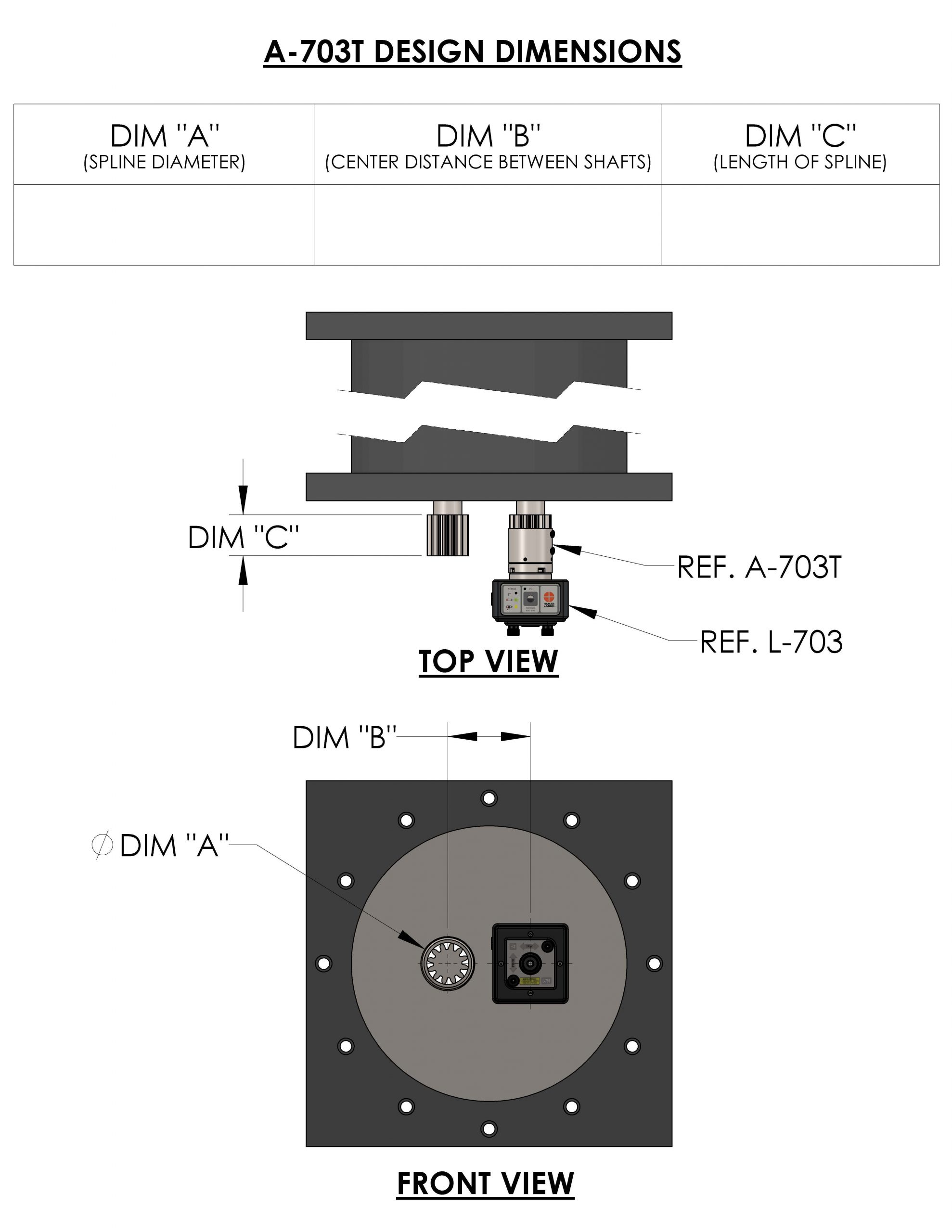

Dimensions:

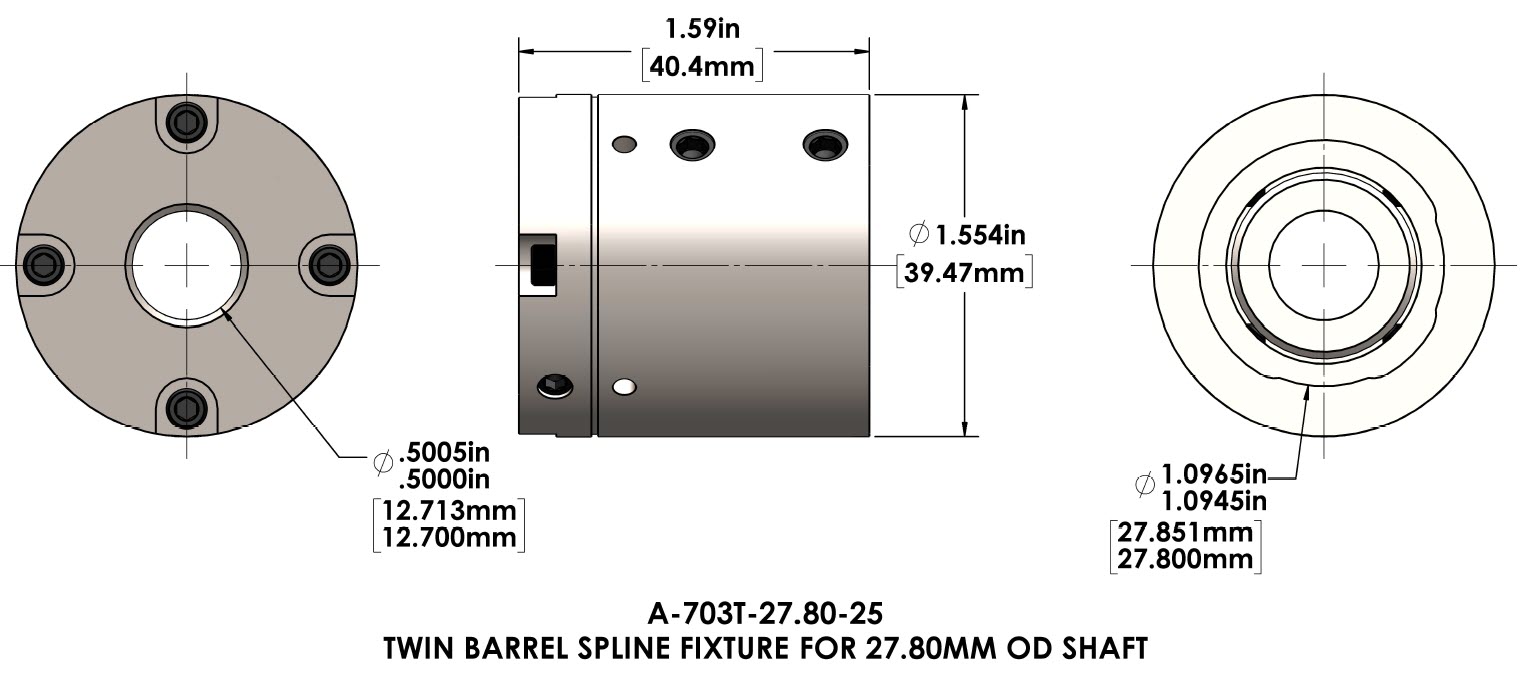

Mounting dimension varies and is customized to the shaft OD. See drawing for other dimensions.

OD Variance Range:

Accommodates ±.020 in. (±0.5 mm) diameter change from nominal.

Mounting Plate Adjustment Range:

±.025 in. (±0.64 mm)

Mounting Hole Diameter:

.4995 in. (12.687 mm) for L-703 Laser Mounting Stud

Material:

404 stainless steel

Drawings

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com