Hamar Laser Awarded U.S. Air Force Contract for Surface Plate Calibration System

$2.6 million contract with AFMETCAL for up to 84 L-703SP Surface Plate Calibration Systems over four years

Hamar Laser Instruments, Inc., a world leader in laser alignment and calibration systems, announces that the U.S. Air Force Metrology & Calibration Office (AFMETCAL) in Heath, Ohio awarded the company a multi-year contract for its L-703SP Surface Plate Calibration System on August 22.

Under the U.S. Air Force contract, valued at more than $2.6 million, AFMETCAL anticipates acquiring up to 84 Hamar Laser L-703SP Surface Plate Calibration Systems over a four-year period for various Air Force bases and Air National Guard bases throughout the U.S., including Alaska and Hawaii.

“As a veteran-owned manufacturer, we are very proud to be supplying the L-703SP Surface Plate Calibration System to the Air Force’s metrology labs throughout the United States,” said Rod Hamar, president of Hamar Laser Instruments. “We have worked very hard to make this the best surface plate calibration system available in the marketplace and winning this contract speaks volumes to the success of our efforts.”

“Our competition under AFMETCAL’s solicitation was electronic levels,” continued Hamar. “Electronic levels are the most widely used tool for surface plate calibration, but are slower, not as repeatable as our L-703SP and do not offer features like customized software, straightedges, measuring increments down to .38 in., and the corner locating tools that make our calibration process so easy. The U.S. Air Force staff rigorously evaluated and tested the L-703SP and, as this award demonstrates, they believe our geometry laser system is the superior choice.”

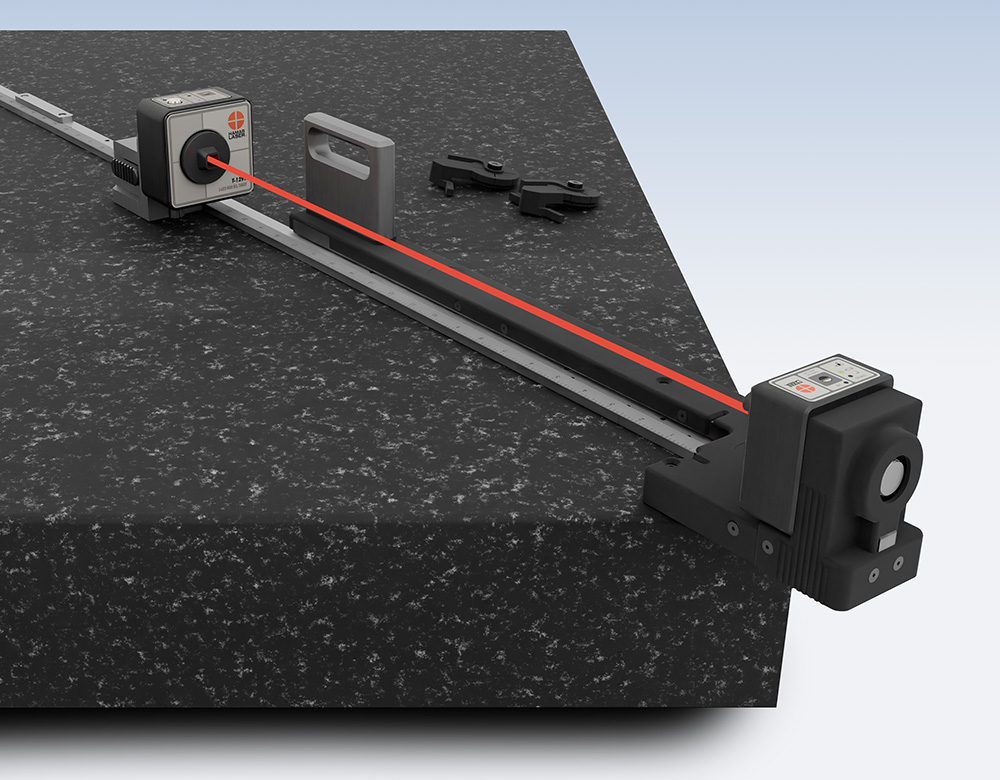

Hamar Laser’s L-703SP Surface Plate Calibration System is a geometry, laser-based calibration system designed from the ground up to quickly check surface plate calibration. It is highly repeatable, with flexible measuring increments, extremely high resolution and accuracy, easy setup and training, and fast data collection. R&D and field testing have shown that the L-703SP significantly reduces the time for calibrating surface plates with conventional methods like electronic levels, autocollimators and laser interferometers.

For further information or to request a free demonstration, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.