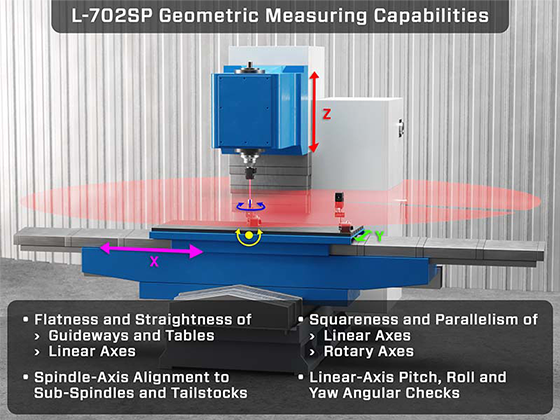

L-702SP Applications

- Lathe and Turning Centers

- Small Machining Centers and Gantries - 3 & 5 Axis

- Small Horizontal Boring Mills & Machining Centers - 3 & 5 Axis

- Presses - Vertical and Horizontal

- MultiTurn/Mill-Turn Machines

- Surface Grinders

- Small Vertical Turret Lathes (VTLs)

Faster, More Accurate Machine

Tool & Spindle Alignment

The L-702SP 5-Axis Machine Tool and Spindle Alignment system is a powerful and versatile alignment system that is highly accurate, fast and easy to set up and can be used for many different machine tool applications. It’s small and compact, perfect for smaller, enclosed machine tools.

Wide Range of Applications

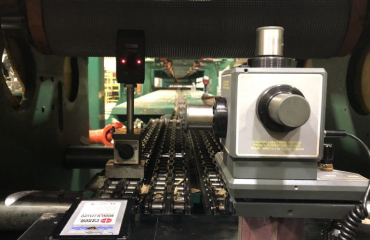

The L-702SP can be used on a wide range of horizontal and vertical machining centers and boring mills, mill turns, injection molding machines, lathe/turning centers, presses and small VTL’s.

Complicated MultiTurn/Mill Turn Alignment Checks Done with Ease

The L-702SP mounts in the main spindle and after a quick setup, you can measure the Z and W axes for straightness and parallelism to the main spindle axis. Then check the main spindle’s alignment to the subspindle. Turn on its perpendicular laser scan plane and start measuring the remaining linear axes of the 3-axis machining head for straightness, as well as squareness and parallelism to the main spindle. Use the L-702RA Right Angle Spindle Fixture and for 1 additional setup to get the straightness, squareness & parallelism of the rest of the axes.

Alignment Data in 15 Minutes

Insert the L-702SP into the spindle or the L-702MB Magnetic Base fixture and after a quick 15-minute setup, you’re getting data.

Easy to Learn & Use

Our systems operate similar to optics and other familiar methods. making them easier to learn and reducing training requirements which can dramatically improve machine performance and reduce scrap rates.

High Resolution and Accuracy

The L-702SP’s laser plane is flat to .00003 in/ft (0.0025 mm/m) and is square to the “plumb” beam to .00006 in/ft (0.005 mm/m). The T-1295 5-Axis Target has a resolution of .00002 in. (0.0005 mm) for center and has 2 angular optics with resolution up to .00004 in/ft. The T-1296 5-Axis Target has double the resolution of the T-1295 but less measuring area.

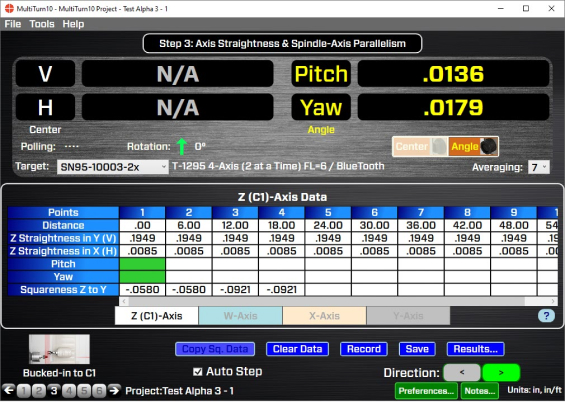

MultiTurn10 Software for Data Recording and Analysis

MultiTurn10 Software was designed for the L-702SP to record data for the various axes on lathes, multiturn machines and machining centers. It features a 6-step process that guides you through the laser setup and data-taking process. The data is then analyzed using least-squares, best fit analysis to generate the alignment results and graphs. Results can be printed to paper or PDF.

Reduced Alignment Downtime

L-702SP offers faster alignment checks with reduced setups and real-time alignment data.

Ultra-Accurate Measurements

Resolution to 0.25 microns. Accuracy up to 0.0013 mm/m.

Years of Experience

We know what works…and

what doesn’t. Try us and see!

Advantages vs. Interferometer Methods Expand +

- Same ultra-high accuracy but easier and faster to setup

- Up to 50% faster alignments

- 2-3 setups vs. 6-8 on a 3-axis machining center

- Re-align errors with real-time data updating vs. static measurements

- Squareness measurements are built into the lasers, avoiding setup of finicky “squareness optics”

- Simultaneous multi-axis alignment checks vs. single-axis checks

- Check alignment of guideways and columns without machine power

Advantages vs. Traditional Methods Expand +

- Up to 10x higher accuracy than levels, straight edges, indicators, etc.

- 1 laser system vs. 4-5 traditional measurement tools

- Ultra-high resolution up to .00001 in (0.00025 mm)

- Up to 75% faster

- Measure entire length of X, Y, W & Z axes up to 100 feet (30 m) for straightness and squareness

- Difficult alignment checks are made easy, such as: bed twist, vertical roll and rotary-axis parallelism

- Simultaneous multi-axis alignment checks vs. single-axis checks

- Real-time data displays automatically update with each adjustment

What Makes Hamar Better?

Ultra-Accuracy

Our laser planes have a flatness accuracy of up to .000015 in/ft. (0.0013 mm/m), flatter than any competing laser, usually by a factor of 8!

High-Speed Alignments

Renowned for their ease of use and fast setups, our systems significantly speed up alignments with real-time data feedback and simultaneous multi-axis adjustment.

Versatility

With 16 different laser alignment products, we have a laser to fit virtually any alignment application for checking concentricity, flatness, straightness, squareness, parallelism, rotation axis collinearity and spindle tramming.

Alignment Experience

More than 5 decades of alignment experience goes into every product, along with our 28 patents! We know laser alignment!

Innovation

We design innovative laser systems engineered for specific applications, not inferior and under-performing “one-size-fits-all” products.

Service

Family owned and operated, we make and service our lasers right here in the USA, providing our customers with a high level of personal service.

What Our Customers Say

"We’ve been using a Hamar Laser alignment system for 15 years. When anybody sees it in action, they see how accurate it is, how it shows alignment data in real time and how easily the results can be repeated...

Read More...

"I want to give you some feedback on our first alignment with our new Hamar system [L-743 Ultra-Precision Triple Scan laser]. We used it to install and align a new bridge mill...

Read More...

"I am very impressed with the overall fit and finish of everything. The Kaisen foam is well designed and every component has a well thought out home. The position and orientation of each component... Read More...

"We have been using Hamar laser equipment for about 14 years and have had nothing but great support from your staff all around, Read More...