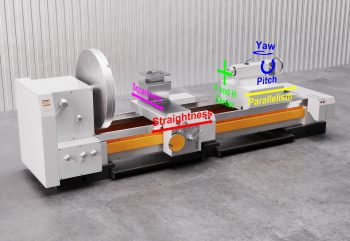

L-700 Lathe Alignment System

Hamar Laser’s patented 4-axis L-700 Lathe & Turning Center Spindle Alignment System is a powerful alignment tool that offers unparalleled accuracy, easy setup and significant savings for aligning spindles to subspindles and headstock spindles to lathe beds and tailstocks. It is also an excellent tool for rotary dial and transfer-line spindle alignments. For over 20 years, the L-700 has been helping companies reduce tooling costs and scrap rates while increasing their productivity and profitability.

System Highlights

- Fast: Easy setups let you do a quick alignment check in 15 minutes and get full alignment data in 25-30 minutes on most machines.

- Easy: Laser and target mount directly into the spindle and tailstock, respectively, allowing the entire length of even the largest lathes to be quickly and easily aligned without changing setups, replacing cumbersome and impractical alignment test bars.

- Accurate: Ultra-high resolution of .00001 in. (0.00025 mm) combined with software to correct mounting errors produces a very accurate alignment, less than .0001 in. (0.0025 mm) and .0001 in/ft (0.0083 mm/m) under good environmental conditions.

- Lathe9 Software: Large, easy-to-see alignment displays, live alignment data and spindle graphics, and a 6-step procedure guide users through the alignment with on-screen help instructions.

- Spindle8 Software: Large, easy-to-see alignment displays, live alignment data and spindle graphics, and a 4-step procedure guide users through aligning spindles to master parts on transfer-line spindle applications.

Key Features

- The laser and target both offer a .500 in. (12.7 mm) mounting stud for simple fixturing to hold them in place.

- Center resolution of .00001 in. (0.00025 mm) and angular resolution of .00001 in/ft (0.0008 mm/m).

- Live measurement data in 4 axes (V center, V angle, H center & H angle) simultaneously.

- Windows 7/8/10-based Lathe9 Software with large, color graphics corrects mounting errors, calculates shim values and provides an alignment report showing all the alignment parameters of lathe alignment.

- L-700 mounts in the spindle to project its axis of rotation out to 100 ft (30 m).

- Vertical and horizontal adjustments for both angle and center to precisely adjust the laser to the spindle’s axis of rotation.

- Laser runs for up to 8 hours on a standard, replaceable 9-volt battery.

- Compact and rugged 4 x 2.9 x 1.7 in. (101 x 74 x 45 mm).

- Only needs 10 in. (254 mm) of space between spindle and tailstock or sub-spindle.

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

- Cylindrical, OD/ID Grinders

- Horizontal Boring Mill Indexing Checks for Deep-Bore Applications

- Rotary Dial Machines

- Transfer-Line Spindle Alignments

- Turning Centers and Lathes

The L-700 is a straight-line laser that can be used for aligning the critical components of lathes, spindle boxes of large rotary-dial machines, the output shaft to the centerline of a twin-barrel extruder and many other applications.

The system includes a battery-operated laser with center and angle adjustments, a target that measures in 4 axes simultaneously, a computer interface with .00002 in. (0.0005 mm) resolution, a target calibration fixture and a portable computer with Hamar Spindle8 alignment software. For aligning dual or multiple spindle machines, a second target, laser and interface can be added.

Complicated Lathe Alignment Checks Done with Ease

Measure headstock spindle-axis parallelism with the lathe-bed and saddle guide-rails, headstock-to-tailstock alignment and spindle-to-subspindle alignment. With a measuring range of up to 65 feet (20 m), even the longest lathe bed is easy to measure for parallelism to the spindle axis, eliminating the need for expensive and heavy test bars.

High Resolution and Accuracy Improves Part Quality

The L-700’s ultra-high resolution of .00001 in. (0.00025 mm) combined with Lathe9 software to correct mounting errors produces a very accurate alignment, less than .0001 in. (0.0025 mm) under good environmental conditions. This extremely high level of accuracy can dramatically improve machine performance and reduce scrap rates.

Live 4-Axis Data Speeds Alignment by 70%

The T-261A’s 4 alignment values update in real time, so without changing the setup, alignment errors can be quickly fixed, while watching Lathe9 software’s 4-axis display update with each adjustment. Lathe9 software also quickly collects the lathe bed’s straightness data, analyzes it, recommends shim and moves values for headstock and tailstock alignments. In most cases, alignment times can be reduced by 60-70%

Simultaneous 4-Axis Target

The T-261A 4-axis target measures both the horizontal and vertical center and horizontal and vertical angular readings simultaneously. This combined with Lathe9 Software allows you to see all 4 alignment axes updating as you make mores to the headstock or tailstocki. This makes checking and correcting the alignment of the lathe’s components much easier and faster.

Alignment Data in 15 Minutes

The L-700 Spindle Alignment System is so easy to set up that you can do a quick alignment check in 15 minutes and the full alignment data in 25–30 minutes on most lathes. Our Lathe9 Software even corrects for mechanical mounting errors to provide the most accurate lathe alignment on the market today!

Lathe9 Built-In, 6-Step Alignment Procedure

An easy-to-follow, 6-step alignment procedure is built right into Lathe9, along with popup instructions, that makes what can be a complicated alignment much simpler and easier to learn. Large color graphical displays allow the alignment data to be seen up to 20 feet (6.5 m) away.

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser