L-708 Internal Bore Laser Systems

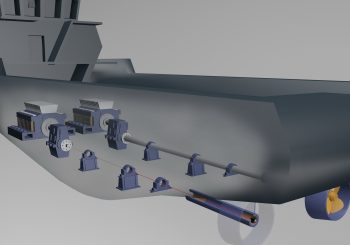

Hamar Laser’s L-708 (Standard) and L-708LD (Long Distance) Bore Alignment Systems are part of a series of bore alignment systems that are the most accurate, versatile and portable bore alignment systems on the market. The L-708 and L-708LD are designed specifically for those applications where it is hard to mount a bore laser externally, such as stern tube bearings, and offer the ability to be inserted directly into a self-centering bore adapter for easy and fast insertion into the bore. This means bore alignments with the L-708 and L-708LD are very fast and very accurate.

System Highlights

- Fast: 15-minute setup time. Measure each bore in seconds!

- Easy: Unique self-centering adapters are easy to insert into tight spaces.

- Accurate: Provides a resolution of .00002 in. (0.0005 mm) and a laser centering accuracy to .0012 in. (0.03 mm). Centering repeatability is .0002 in. (0.005 mm).

- Versatile: Many target and adapter options for bore diameters from 3.75 in. (95.25 mm) to 40 in. (1 m) or more.

- Bore9 Software: Record bore alignment, calculate straightness results and print reports using optional Windows-based Bore9 Software.

Key Features

- Built-in coarse and fine horizontal and vertical angular adjustments for quick referencing.

- Designed to fit into reference bores using our A-514 Self-Centering Bore Adapters to save time and simplify the setup.

- L-708 has a range of 100 feet (30 M). L-708LD has a range of 200 feet (60 M).

- Visible laser beam straight to .0001 in. in 10 feet (0.0025 mm in 3 meters) or .001 in. in 100 feet (0.025 mm in 30 meters).

- R-1307-2.4ZB Readout supports both wireless and cabled targets with a wireless range up to 150 feet (45 meters) with wireless range up to 150 feet (45 M).

- System resolution of .00002 in. (0.0005 mm).

- Self-centering target, accurate to .0012 in. (0.03 mm) and repeatable to .0002 in. (0.005 mm).

- For higher accuracy applications (.001 in.) the L-708 can be mounted externally using the L-111 Laser Stand with the L-102 Beam Translator.

- System handles a large range of bore IDs from 3.75 in. (92.25 mm) up to 40 in. (1,016 mm).

- Windows-based Bore9 software with large color graphics to record and analyze bore straightness and alignment data.

- Dynamic or live display of component misalignment.

- Portable enough to fit into small carrying case.

- Laser runs for up to 8 hours on a standard, replaceable 9-volt battery.

- Optional A-510SM Small-Bore Target easily accommodates bores as small as 1.5 in. (38.1 mm).

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

- Hinge Line Spherical Bearing Bores

Automotive, Marine & Locomotive Engine Blocks

- Crankshaft and Camshaft Line Bores

- Cylinder Straightness

Manufacturing & Metalworking

- Boring Bar Bearing Alignment

- Deep-Bore Straightness Checks on Parts

Marine

- Propeller Shaft Bearing Bores

- Stern Tube Alignment

Fast Setup And Even Faster Measurements

With simplified fixturing and self-centering targets, the L-708 system can be set up in as little as 15 minutes. Since it literally takes less than a minute to insert the target/adapter into a bore to take a measurement, in most cases bore straightness data can be taken and analyzed in 30 minutes or less. This means that even the longest bore application can be measured in just minutes versus hours for optics, tight wire or other laser systems. Nothing is faster than the L-708 Bore Alignment System!

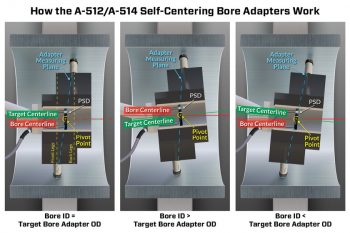

Self-Centering Laser Adapters for Fast Setup

The L-708 Bore Laser is designed to work with our A-514 A/B/C Self-Centering, Adjustable Bore Adapters, which allow the laser to be inserted into a bore, vastly speeding up the laser setup. This self-centers the laser to .001 in. (0.025 mm) accuracy. All that is left after inserting the laser is to adjust the angle of the laser beam and the setup is done.

The laser has a mounting surface of 1.2498 in. (31.745 mm) and the laser beam is centered to this OD to within .0003 in. (0.08 mm). The L-708 Laser is equipped with coarse and fine angular adjustments necessary to set the laser beam to the center of the far reference target.

- The L-708 used for applications up to 110 feet (33 m).

- The L-708LD Long-Distance Bore Laser can be used out to 200 feet (60 m).

-

[#Beginning of Shooting Data Section] Nikon D800 2012/09/05 17:21:01.90 Time Zone and Date: UTC-5, DST:OFF Lossless Compressed RAW (12-bit) Image Size: L (4800 x 3200), DX Lens: 28-70mm f/2.8D Artist: AL FERREIRA PHOTOGRAPHY Copyright: AL FERREIRA -www.afpltd.com Focal Length: 56mm Exposure Mode: Manual Metering: Spot Shutter Speed: 1/160s Aperture: f/18 Exposure Comp.: 0EV Exposure Tuning: ISO Sensitivity: ISO 100 Optimize Image: White Balance: Color Temp. (5000K), 0, 0 Focus Mode: Manual AF-Area Mode: Single AF Fine Tune: OFF VR: Long Exposure NR: OFF High ISO NR: ON (Normal) Color Mode: Color Space: Adobe RGB Tone Comp.: Hue Adjustment: Saturation: Sharpening: Active D-Lighting: OFF Vignette Control: OFF Auto Distortion Control: OFF Picture Control: [SD] STANDARD Base: [SD] STANDARD Quick Adjust: 0 Sharpening: 3 Contrast: 0 Brightness: 0 Saturation: 0 Hue: 0 Filter Effects: Toning: Map Datum: Dust Removal: 2012/08/17 08:50:24 [#End of Shooting Data Section]

Patented Self-Centering Target & Adapters – The Key To The System

The A-512 2-Axis Bore Target and the L-708 Bore Laser are designed specifically for our A-514 line of self-centering bore adapters. This unique feature allows the laser and target to be inserted into reference bores without any mechanical setup, such as bore sweeping or the need to rotate the target to determine mounting errors (a common problem with most other systems). All you need to do is insert the laser, target and their A-514 bore adapters into the reference bores and make sure they are oriented at 12:00. In just a couple minutes, the laser will be set up and ready to take measurements.

Then it takes just seconds to measure each internal bore for alignment. The laser and target are concentric to their housings to within .0003 in. (0.0075 mm). When used with the A-514 adapters, the target and laser are centered to the bore within .0006 in. (0.015mm) accuracy.

System Handles Large Range of Bores

Our adjustable A-514 A/B/C Self-Centering Bore Adapters can handle any bore from 3.75 in. (92.25 mm) up to 40 in. (1,016 mm) or more. The system offers 3 bore adapters and a leg-setting gage to set the adapters to the nominal bore ID. For bores from 2.25 in. (57.2 mm) to 3.75 in. (92.3 mm), we offer our A-512 Target and A-512STA Self-Centering Adapter Hub and M-705CL Customized Measuring Legs.

Simple Readout with High Resolution and Accuracy

The R-1307 has a display resolution of .0001 in. (0.001 mm). There is no complicated software to learn in order to use the system, which minimizes training requirements. For those who want to document the alignment and produce a report, there is no easier bore alignment program to use than our Bore9 software.

The system is accurate to .0006 in. (0.01 mm) and repeatable to .0002 in. (0.005 mm). Under good environmental conditions, the L-708 Laser is capable to measure to .005 in. (0.13 mm) over the whole 100 feet (30 m) range. By mounting the laser externally with L-111 Laser Stand accuracies of .0003 in. (0.0075 mm) in 10 feet (3.1 meters) can be achieved.

Live Alignment Data Saves Even More Time

As with all of our laser alignment system, the A-512 Bore Target provides live alignment data via our R-1307 readouts. This means once the target is installed in a bore and you are ready to align it, you just watch the readout continuously update as you adjust the bore, supporting pillow blocks or bearing sleeves. When the readings are zero, you’re done!

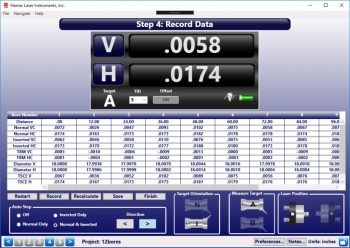

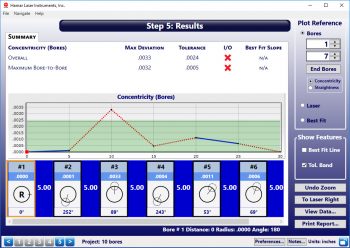

Optional Bore9 Alignment Software

Hamar Laser’s Bore9 software records alignment (concentricity) data for up to 50 bores. It also measures straightness of cylinders and can measure diameter changes when used with our self-centering targets in Measure Mode. It supports all of Hamar’s past and present bore alignment equipment and features a step-by-step guide to help the user through the software.

Measure Bore Angle In Seconds

To check for bore angle relative to the centerline, just take a measurement at the front or back of the bore and any difference shows the angle! Adjust the front and back of the bore to read zero and it’s aligned! Also with our unique design, our target only needs a few inches of bore width to take a measurement.

Wireless Data Downloading And Transfer

For long-distance applications, the R-1307 Readout can be configured with a 2.4GHz Zigbee® radio and transmit its data up to 150 feet (45 M). The data can be received by a second R-1307, which is very useful when bucking-in (setting up) the laser to reference targets that are at distances greater than 15 feet, or it can also be received by the A-910-2.4ZB Computer Interface for automatic downloading into our Bore9 Software.

-

[#Beginning of Shooting Data Section] Nikon D800 2012/09/05 14:32:18.80 Time Zone and Date: UTC-5, DST:OFF Lossless Compressed RAW (12-bit) Image Size: L (7360 x 4912), FX Lens: 28-70mm f/2.8D Artist: AL FERREIRA PHOTOGRAPHY Copyright: AL FERREIRA -www.afpltd.com Focal Length: 60mm Exposure Mode: Manual Metering: Spot Shutter Speed: 1/160s Aperture: f/22 Exposure Comp.: 0EV Exposure Tuning: ISO Sensitivity: ISO 100 Optimize Image: White Balance: Color Temp. (5000K), 0, 0 Focus Mode: Manual AF-Area Mode: Single AF Fine Tune: OFF VR: Long Exposure NR: OFF High ISO NR: ON (Normal) Color Mode: Color Space: Adobe RGB Tone Comp.: Hue Adjustment: Saturation: Sharpening: Active D-Lighting: OFF Vignette Control: Normal Auto Distortion Control: OFF Picture Control: [SD] STANDARD Base: [SD] STANDARD Quick Adjust: 0 Sharpening: 3 Contrast: 0 Brightness: 0 Saturation: 0 Hue: 0 Filter Effects: Toning: Map Datum: Dust Removal: 2012/08/17 08:50:24 [#End of Shooting Data Section]

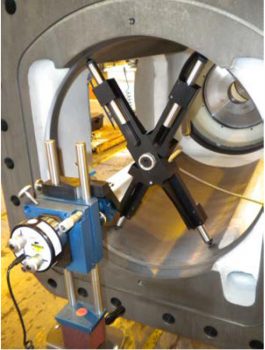

Compressor "Cut-Away" Bore Alignment

The L-708, combined with the L-111 Laser Stand and L-102 Laser-Beam Translator, are mounted outside of the compressor bore and our special version of the A-514 Self-Centering Bore adapter is used on the top and bottom 60 degrees of the “cut away” bores on the compressor to align the laser to the near and far bores. The target/adapter are then moved to the cross-head and other components to check and align the bores. With care, accuracies of 0.0005 in. (0.01 mm) can be achieved. The alignment is up to 50% faster and two times more accurate than tight wire methods.

Downloads

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser