Description

Designed primarily for high-accuracy flatness, straightness and squareness measurements of machine tools, the L-743 Ultra-Precision Triple Scan® Laser has 3 auto-rotating laser planes, 2 vertical and 1 horizontal. All 3 laser planes are flat within 0.5 arc seconds (.00003 in./ft. or 0.0025 mm/m) in a 360º sweep and 0.25 arc second in a 90º sweep. The top-to-side and top-to-rear laser planes are perpendicular within 1 arc second (.00006 in./ft. or 0.005 mm/m). The 2 side and rear laser planes are perpendicular to within 3 arc seconds. It also features 3-arc-second illuminated level vials with optional L-740SP Split-Prism Upgrade to split-prism level vials accurate to 1 arc-second.

The laser is mounted on an adjustable base with coarse and fine pitch, roll and yaw adjustments, so that each laser plane can project the measurement reference out to 100 feet (30.5 m) in radius in all directions. The laser is completely self-contained and can operate on battery or AC power. It comes with a 10,000 mAh lithium ion rechargeable battery pack for up to 16 hours of continuous use with all 3 planes running.

Since the L-743 has 3 laser planes, multiple machine axes can be aligned and measured at the same time. In addition, laser planes make formerly difficult alignment measurements, like roll in horizontal and vertical machine axes, a very easy process.

The laser can project the measurement reference out to 100 feet (30.5 meters) in radius for each laser plane, so surfaces up to 200 feet (61 meters) can be measured in 1 setup.

Applications

For alignments with tolerances of .00003 in./ft. or 0.0025 mm/m or greater

Measuring and aligning:

- The flatness and straightness of almost any surface (squares, frames, ways, flanges, circles, etc.) horizontal or vertical.

- Leveling almost any surface (squares, frames, ways, flanges, circles, etc.

- The straightness of horizontal and vertical machining axes

- The squareness of vertical to horizontal surfaces or 2 vertical surfaces, up to 100 feet (30.5 m) long

- The parallelism of vertical or horizontal surfaces

- Checking plumb of a vertical surface up to 100 feet (30.5 m) long

- Checking machine tool guideway twist and parallelism between guideways

- Measuring surfaces up to 200 feet (61 meters) long with one setu

Machine tools:

- Machining centers, gantries and lathe guideways and beds

- Gantries, large and small

- Roll grinding machines

- Roll forming machines

- High-precision water-jet cutting and laser-cutting machines

- Horizontal boring mills, floor mills and VMC/HMC machining centers

- Surface grinders

- Vertical turning lathes (VTLs)

Other machines:

- Injection molding machines and presses for measuring platen parallelism and squareness to tie bars and guideways

- Aircraft assembly (seat track alignment, setting water, butt and station planes, wing-to-body and body-to-body join alignment, etc.)

Roll alignment:

- Film lines

- Paper mills

- Printing presses

Features

- 3 continuously rotating laser planes (1 horizontal and 1 vertical) with operational range of 100 feet (30.5 m) in radius

- High accuracy: laser planes flat to 0.5 arc seconds (.00003 in./ft. or 0.0025 mm/m) in a 360º sweep and 0.25 arc seconds in a 90º sweep

- Planes are mutually square with an accuracy of up to 1 arc sec (.00006 in./ft. or 0.005 mm/m)

- Includes Pitch/Roll/Yaw adjustment base with coarse and fine adjustments

- Standard illuminated levels accurate to 3 arc second (.00018 in./ft. or 0.015 mm/m)

- Optional L-740SP high-accuracy, split-prism illuminated levels accurate to 1 arc second (.00006 in/ft. or 0.005 mm/m)

- Uses A-1519-2.4ZB Single-Axis, Wireless Targets – 1.2 in. (33 mm) PSD, .00002 in (0.0005 mm) resolution

- Optional Ultra-Accuracy Target: A-1520-2.4ZB Single-Axis, Wireless Targets – .39 in. (10 mm) PSD, .00001 in. (0.00025 mm) resolution

- Wireless targets provide real-time alignment data updating simultaneously

- Align and monitor multiple axes simultaneously using up to 99 targets at the same time

- Usually 1-2 setups per machine

- Setups typically take 10-20 minutes or less

- Short warm-up

- Optional Windows Win7/8/10 software for quickly recording and analyzing machine geometry data

- Battery or AC powered

- Laser and targets fit into portable shipping case

Specifications

Base: 4.8 lbs. (2.2 kg)

Battery Pack: 1 lbs (0.5 kg)

L-123 Base: Aluminum

.160 in. (4.06mm) beam diameter

Equivalent to 0.25 arc seconds (.000015 in./ft. or 0.0013 mm/m) in a 90º sweep

Equivalent to ± .000075 in. (0.002 mm) in a 90º sweep

Top-to-rear laser plane: <1 arc second (.00006 in./ft. or 0.005 mm/m)

Rear-to-side laser plane: <3 arc second (.00018 in./ft. or 0.015 mm/m)

Optional M-124-Lipo 10,000 mAh LiPo Rechargeable Battery Pack

Optional Replaceable 9V Battery Pack

Fine: ± 0.15º

Fine: 0.17 arc sec (.001 in./100 ft. or 0.025 mm/30m)

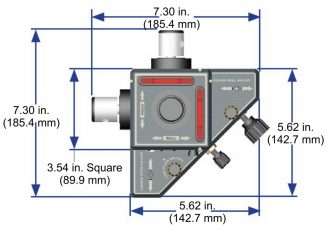

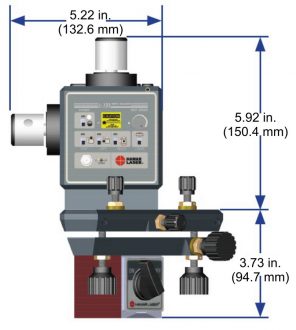

Drawings

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com