L-733 Precision Triple Scan® Laser

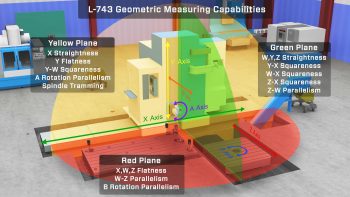

Hamar Laser’s L-733 Precision Triple Scan® Laser Alignment System is a highly accurate and versatile alignment tool. This powerful yet easy-to-use system is ideal for quickly and accurately checking and fixing the geometry of most lower-accuracy machining centers and excels at many other demanding applications. Our Ultra-Precision Series L-743 and Precision Series L-733 are the only alignment systems in the world to offer 3 automatically rotating laser planes with the extreme high accuracy needed for today’s ever-tightening tolerances. This creates a powerful tool that not only measures surface flatness, squareness and straightness, but fixes complex alignment problems in a fraction of the time needed with conventional methods.

System Highlights

- Fast: Data updates in real time to align boring mills, gantries and machining centers up to 70% faster than traditional methods or laser interferometers.

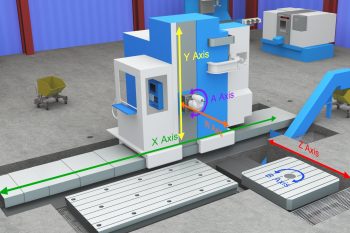

- Easy: Measures the three main axes of a machine at the same time for flatness, straightness and squareness, and checks any additional axes for parallelism usually with the one setup.

- Accurate: Precision laser planes have a flatness of accuracy .00012 in/ft. (0.01 mm/m or 2 arc seconds) in a 180º/360° sweep and .00006 in/ft. (0.005 mm/m or 1 arc second) in a 90º sweep.

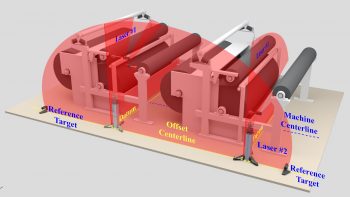

- Versatile: Ideal for nearly all types of lower-accuracy machine tools, as well as many other applications including aircraft assembly, automotive transfer lines, injection molding machines, roll alignment and laser and water-jet cutting machines.

- Smart: Powerful Windows-based alignment software, combined with advanced wireless interfaces, makes collecting and analyzing alignment data fast and easy.

Key Features

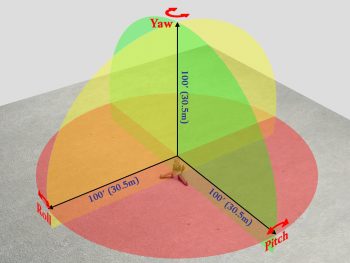

- 3 continuously rotating laser planes with operational range of 100 ft (30.5 meters) in radius.

- Laser planes have a flatness of accuracy .00012 in/ft. (0.01 mm/m or 2 arc seconds) in a 180º/360° sweep and .00006 in/ft. (0.005 mm/m or 1 arc second) in a 90º sweep.

- Planes are mutually square up to .00012 in/ft. (0.01 mm/m).

- Includes L-123 Pitch/Roll/Yaw base with coarse adjustments.

- Standard Targets: A-1519 2.4ZB Wireless Target with ±.55 in. (12.7 mm) Measuring Range and .00002 in. (0.00058 mm) Resolution.

- Real-time data updating so you can watch the alignment values update as the machine is being adjusted.

- Backlit levels accurate to 3 arc seconds .00018 in/ft. (0.015 mm/m). Upgrade to Split-Prism levels for accuracy to .00006 in/ft (0.005 mm/m).

- Typical setup time 20 minutes or less.

- Battery or AC powered.

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

Aerospace

- Aircraft Interior Alignment (Storage Bins, Galleys, etc.)

- Body-to-Body Join Assembly

- Floor Beam Alignment

- Jig/Tooling Calibration and Leveling

- Seat-Track Alignment

- Wing-to-Body Joining Alignment

Fabricating Machinery

- Laser-Cutting Machines

- Routers

- Saw Mills

- Tube-Bending Machines

- Water-Jet Machines

- Woodworking Machines

Fabrication Alignment

- Agricultural Machinery Assembly

- Large Construction Machinery Assembly

- Locomotive Assembly

- Truck Bed Assembly

- Wind Turbine Flange Parallelism

Machine Tools – Lower Accuracy

- Floor and Spar Mills

- Gantries

- Horizontal and Vertical Boring Mills

- Horizontal and Vertical Machining Centers

- Large-Lathe Beds

- Machine Tool Assembly and Calibration

- Roll-Forming Machines

- Transfer-Line Wing Bases

- Vertical and Horizontal Presses

- Vertical-Turning Lathes (VTLs)

Quality Control

- Checking Flatness, Straightness, Squareness and Parallelism of Large Fixtures and Parts

Roll Alignment

- Aluminum Mills

- Continuous Casting Machines

- Textile Mills

Ship Building

- Gun Bearing Alignment

- LNG Tanker Hull Construction

- Section Alignment and Layout

L-733 Precision Triple Scan® Laser Alignment System

We designed the L-733 Precision Triple Scan® Laser to bring the innovative power of our high-end machine tool geometry lasers to lower accuracy applications like water jet and laser cutting machines, steel and textile mill roll alignments and large fabrication alignment. It has all of the timesaving and useful features of the L-743, with a few minor exceptions: lower accuracy, lower price and a medium adjustment base.

Usually Only Requires One Setup

Like the L-743, the L-733 offers 3 automatically rotating laser planes that not only MEASURE but it also FIX alignment errors in a fraction of the time needed with conventional methods. In most cases, it can align a machining center with only one setup.

High Accuracy at 30% Lower Price

With a price that is 30% lower, the L-733 is an affordable alternative to our high-accuracy machine tool alignment lasers. It features 2 vertical and 1 horizontal continuously rotating laser planes, a pitch, roll and yaw (medium) adjustment base, for setting the laser planes parallel to reference points, 2-arc-second level vials and a powerful magnet for maximum stability.

One of the critical components of any laser system is the straightness or flatness of the laser beam or plane, as this is the reference from which the measurements are made. The 733’s laser planes are flat (in a 360° sweep) and square to 2 arc seconds (0.00012″/ft or 0.01 mm/M). In a 90° sweep, the laser planes are flat to 1 arc second.

High Resolution Wireless Targets

Another critical component of laser alignment systems is the resolution of the targets. This determines how close the measurements can be made.

For higher accuracy applications, our wireless targets (A-1519-2.4ZB and A-1520-2.4ZB) is an ideal alternative. The targets have ±.55 in. (±14 mm) of measuring range, resolutions as low as .00002 in. (0.0005 mm) and can be used up to 100 feet (30.5 meters) from the readout (R-1357-2.4ZB), which uses a Ruggedized Trimble Android PDA and color software to display up to five targets simultaneously.

Alignment Applications

For alignments with tolerances of 0.00015″/ft or (0.01 mm/M) or greater, the L-733 can quickly measure and correct machine geometry with minimal setup for the following applications:

- Machining centers (HBM, VBM, VTL, VMC, HMC, gantries, surface grinders)

- Water-jet and laser-cutting machines

- Vertical and horizontal press alignment

- Roll alignment (rubber, steel, textile and lower accuracy film lines)

- Aircraft assembly (seat track alignment, setting water, butt and station planes, wing-to-body and body-to-body join alignment, etc.)

- Saw mills

- Leveling machine beds and ways

- Checking the alignment of large bearing surfaces and fabrications

- Measuring and aligning:

- The flatness of almost any horizontal or vertical surface (squares, frames, ways, flanges, circles, etc.) or axes.

- The straightness of vertical and horizontal axes

- The squareness of any vertical machine axis or surface to a horizontal axis or surface

- The squareness of any 2 vertical surfaces or axes

- The parallelism of vertical or horizontal surfaces, even if those surfaces are 100 feet (30.5 meters apart)

- Way twist and parallelism between vertical surfaces

- Way twist and parallelism between horizontal surfaces

- Checking plumb of a vertical surface up to 100 feet (30.5 meters)

- Measuring surfaces up to 200 feet (61 meters) long with 1 setup

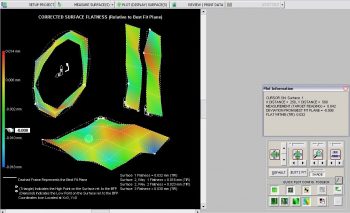

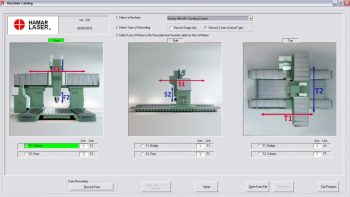

Color Alignment Software

For wireless recording and analyzing alignment data, our color, 3-D flatness and squareness analysis software, Plane5 or Machine Tool Geometry, simplifies and streamlines the data analysis process. Plane5 can measure up to 7 different surfaces in one project setup file and present a color, 3-D graph of the flatness and squareness analysis for each surface. Machine Tool Geometry software can measure and analyze 4 different machining center-type machines. And you can add your own machine configuration as well!.

Downloads

- L-733 – L-743 Machining Center Alignment Brochure – Rev D

- A-1519/A-1520-2.4ZB Type II Wireless Target Manual – Rev G1

- R-1357 PDA Android Data Display datasheet – Rev B2.pdf

- L-106 Datasheet – Rev F

- R-1307B Basic Readout Datasheet -with KS – Rev F2

- S-1388 Plane5 Sample Report Rails Flatness

- S-1388 Plane5 Software Version II – Rev A

- Plane5 Sample Report 3 surfaces

- S-1387 Machine Geo Software – Rev C

- Machine Geo Sample Report

- A-1519-1520 Data Format – Type II – Programmer’s note -1 or 2-axis targets

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser