Description

Lathe10 Lathe Alignment Software

Hamar Laser’s newly updated Windows-based, Lathe10 Lathe Alignment software supports our L-700, L-702SP and L-703 Spindle Alignment laser systems for aligning lathes or other turning-type machines. This comprehensive and easy-to-use program displays real-time, 4-axis alignment data of the headstock to the tailstock. It also checks the straightness of the guideways and parallelism to the main spindle axis. When used with the L-702SP Laser and T-1295 5-Axis Target, Lathe10 can also measure the squareness of cross slides & turrets on lathes and machining axes on multiturn/millturn machines.

Applications

Applications include:

- Cylindrical Grinders

- Lathes

- Screw Machines

- Turning Centers

- Turret Lathes

- Mill-Turn & Multi-Turn Machines

Machine Geometry Measurement:

- Guideway straightness

- Guideway pitch and yaw

- Headstock spindle-axis parallelism to tailstock or turret guideways

- Headstock spindle-axis alignment to: tailstock or turret centers, or subspindle rotation axes

Features

Easy 6-Step Process

Lathe10 guides the user through the alignment with a 6-step process, designed to align a lathe in the most efficient way. First the setup data is entered. Then the guideways are checked for straightness and it is determined if the headstock spindle axis is parallel to the bed. If these geometries are out of spec, they need to be fixed first. Lathe10 then takes data for the headstock spindle alignment to the tailstock or turret and provides a live, 4-axis display of the alignment, along with shim value calculations to align them. Finally, a printed report details the alignment of all the lathe geometries. Results can be plotted, saved, and exported to an Excel spreadsheet for further analysis.

Project Headstock Spindle Axis Out to 100 Feet

By following our simple Step 2 procedure, the laser can be aligned exactly to the spindle axis of rotation, which can then be projected out to 100 feet (30 m) to measure guideway parallelism of even the largest lathe.

Easily Measure Headstock Spindle-Axis Parallelism to Guideways

Lathe9 records the straightness data of the main bed and automatically calculates the guideway straightness and parallelism of the spindle axis to the bed. It can even check parallelism of the saddle or turret guideways if they are separated from the tailstock guideways.

Real-time 4-axis Data Display

The alignment displays the update with each adjustment in four axes: V-center, H-center, V-angle and H-angle. This allows the user to quickly correct misalignment errors and requires no calculations!

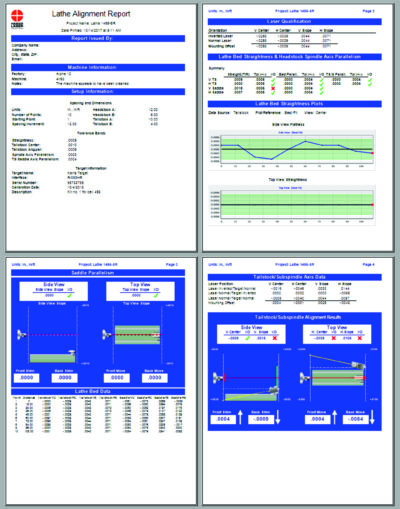

Report Generation

Reports can be customized to show the results relative to the laser or the guideway best-fit line, comments may be added, and the report can be printed with a summary, a graph of the vertical and horizontal straightness, comments and a table showing the recorded data.

Program Features – 6-Step Process

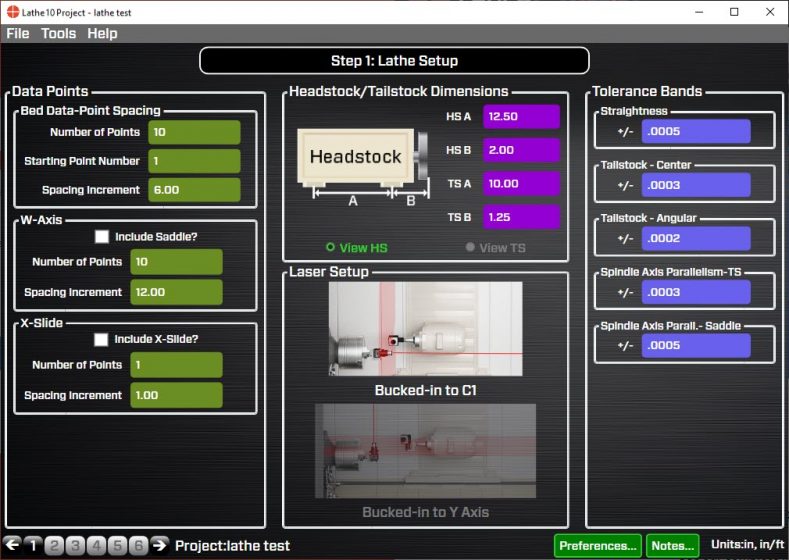

Step 1: Set Up

Enter the headstock and tailstock dimensions, choose the number of points to be recorded and enter the alignment tolerances. The dimensions are used to calculate shims when aligning the headstock, tailstock and/or turrets. The alignment tolerances are automatically applied to the displays, results screen and graphs.

Step 2: Qualify Laser

Step 2 is used to align the laser to the headstock spindle’s rotation axis by following the NORMIN procedure, where one set of data is recorded with the spindle/laser in the NORMal position and a second set is recorded with the spindle/laser in INverted position. Display offsets are automatically applied so the user steers the laser’s 2 angular axes, using the pitch and yaw adjustments, to align the laser beam to spindle’s axis of rotation.

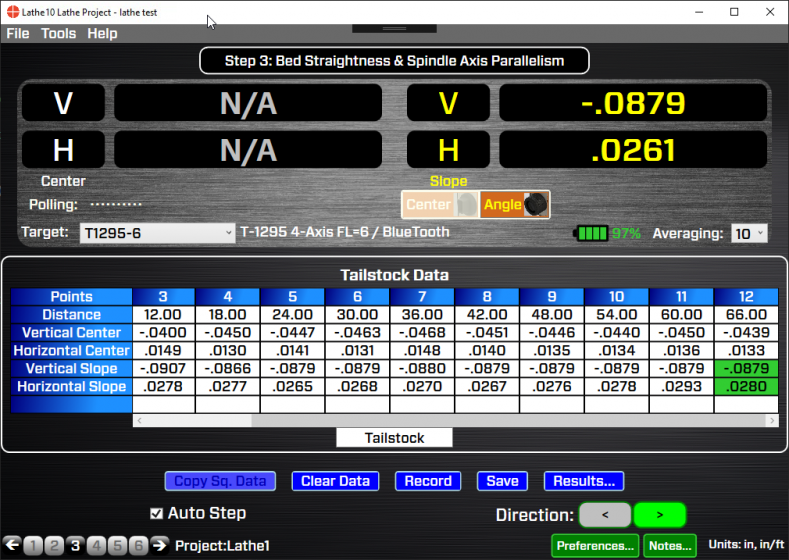

Step 3: Guideway Straightness and Spindle-Axis Parallelism

After qualifying the laser, straightness data is recorded for tailstock guideways, the turret (saddle) guideways or both, using the number of points selected in Step 1. Lathe10 records four axes of data (V-center, H-center, V-angle, H-angle) at each location along both sets of guideways. This is especially helpful where the tailstock and turret (saddle) ride on separate guideways. To take the data, the target is mounted in the tailstock or turret (saddle) and moved along the lathe bed to each point. When finished, click the Results button to view the alignment data.

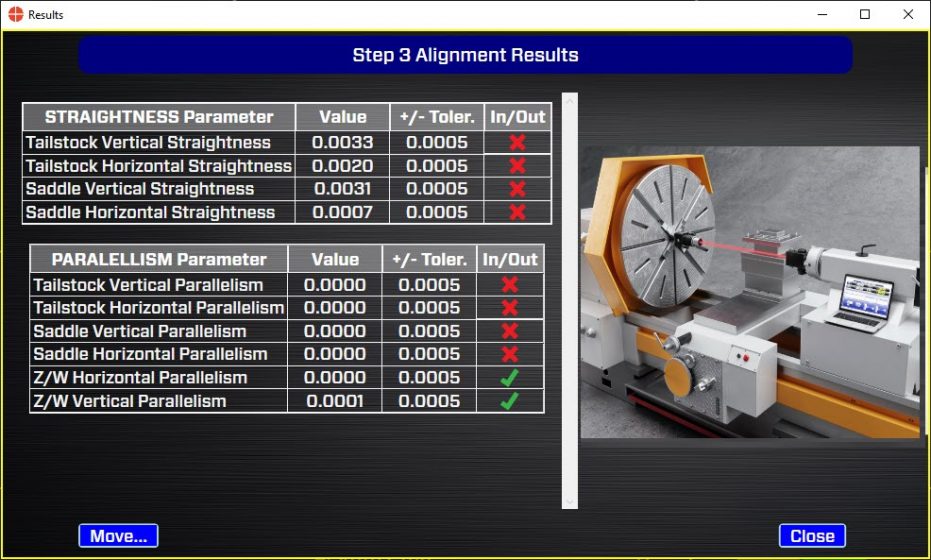

Step 3: Alignment Data Results

After taking data, click the Results button to view alignment results for:

- Tailstock guideway straightness

- Turret (saddle) guideway straightness

- Headstock spindle-axis parallelism to the tailstock guideways and/or turret guideways and the parallelism between the two sets of guideways.

A green check-mark or red X displays if the data is in or out of tolerance, based on the tolerances entered in Step 1.

Step 3: Headstock Spindle-Axis Real -Time Alignment Screen

Click the Move button in Step 3 to open the Headstock Spindle-Axis Real-Time Alignment Screen. In this screen, the headstock may be aligned to either the tailstock guideways or turret (saddle) guideways or an average of both. Shim values are calculated to align the headstock and a live angular display shows whether the alignment is in or out of tolerance.

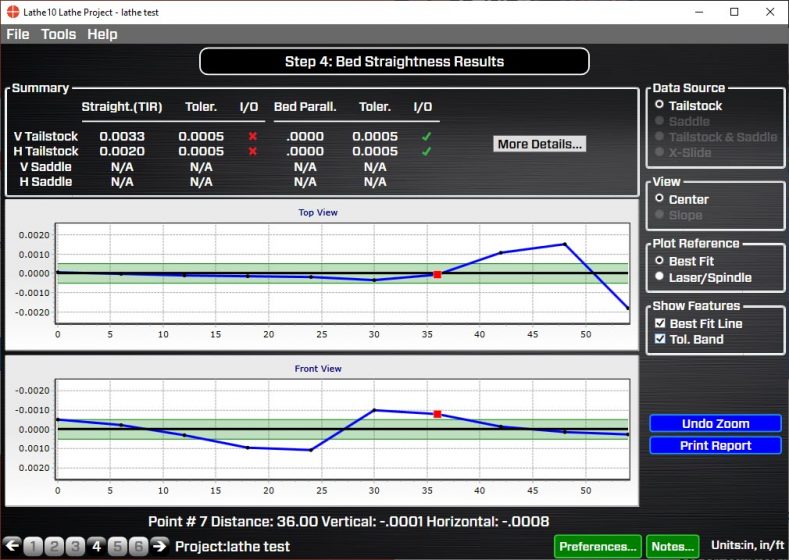

Step 4: Lathe-Bed Straightness Results and Graph

After recording data in Step 3, Step 4 calculates:

- Straightness for each set of guideways

- The parallelism of the main spindle axis to the tailstock guideways and turret guideways

- The parallelism between both sets of guideways.

Results are displayed in the table and are compared against the tolerances defined in Step 1. Straightness is then plotted on a graph, showing whether the data is in or out of tolerance. The user may choose which set of data to plot and also what reference to use for the plot: the laser or the least-squareness, best-fit line. Clicking a point on the graph displays the data for that point.

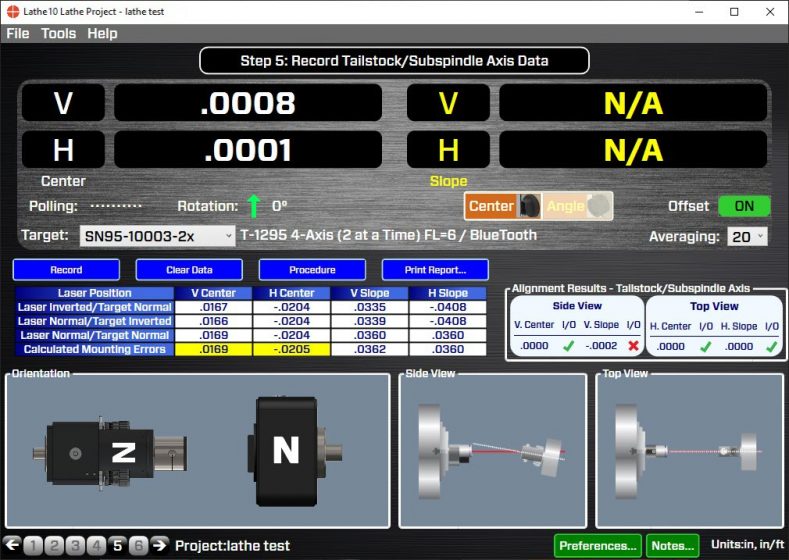

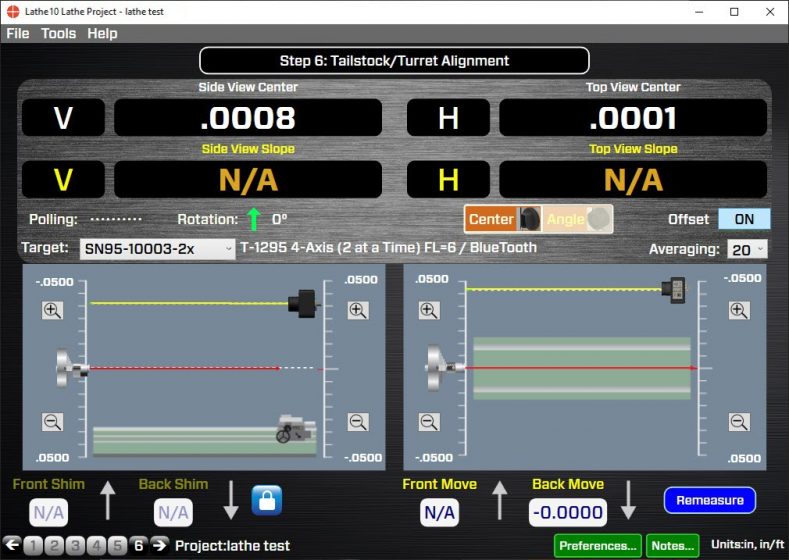

Step 5: Record Tailstock/Subspindle Axis Data

After the headstock spindle axis has been aligned to the lathe’s guideways, Step 5 is used to take data for the alignment of either the tailstock or a subspindle to the headstock spindle axis of rotation. It takes about 3-4 minutes to record the data and on-screen instructions guide you through the procedure. Once the data is recorded, alignment results are calculated and compared against the tolerance and a graphical display illustrates the alignment. Display offsets are also automatically applied to the real-time, 4-axis display to show the alignment of the tailstock or subspindle to the main spindle.

Step 6: Tailstock/Turret Real -Time Alignment Screen

If the data recorded in Step 5 is out of tolerance, the misalignment can be fixed in the Step 6: Tailstock/Turret Alignment screen. Lathe10 automatically applies display offsets so the real-time, 4-axis display shows the actual alignment results. It also calculates the shims necessary to align the tailstock or turret. Real-time spindle graphics (vertical/side view and horizontal/top view) automatically update with each move, showing how the alignment is progressing. When the shim displays turn green, the alignment is complete.

Generating Reports

Specifications

Drawings

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com