Description

The L-703S Lathe/Turning-Center Spindle & Straightness Alignment Laser is the lathe “variant” of the L-703 Laser System. It is a small, battery-operated, diode laser that mounts directly into spindle chucks and collets. It is used for aligning headstock spindle axes to guideways and sub-spindles and tailstocks.

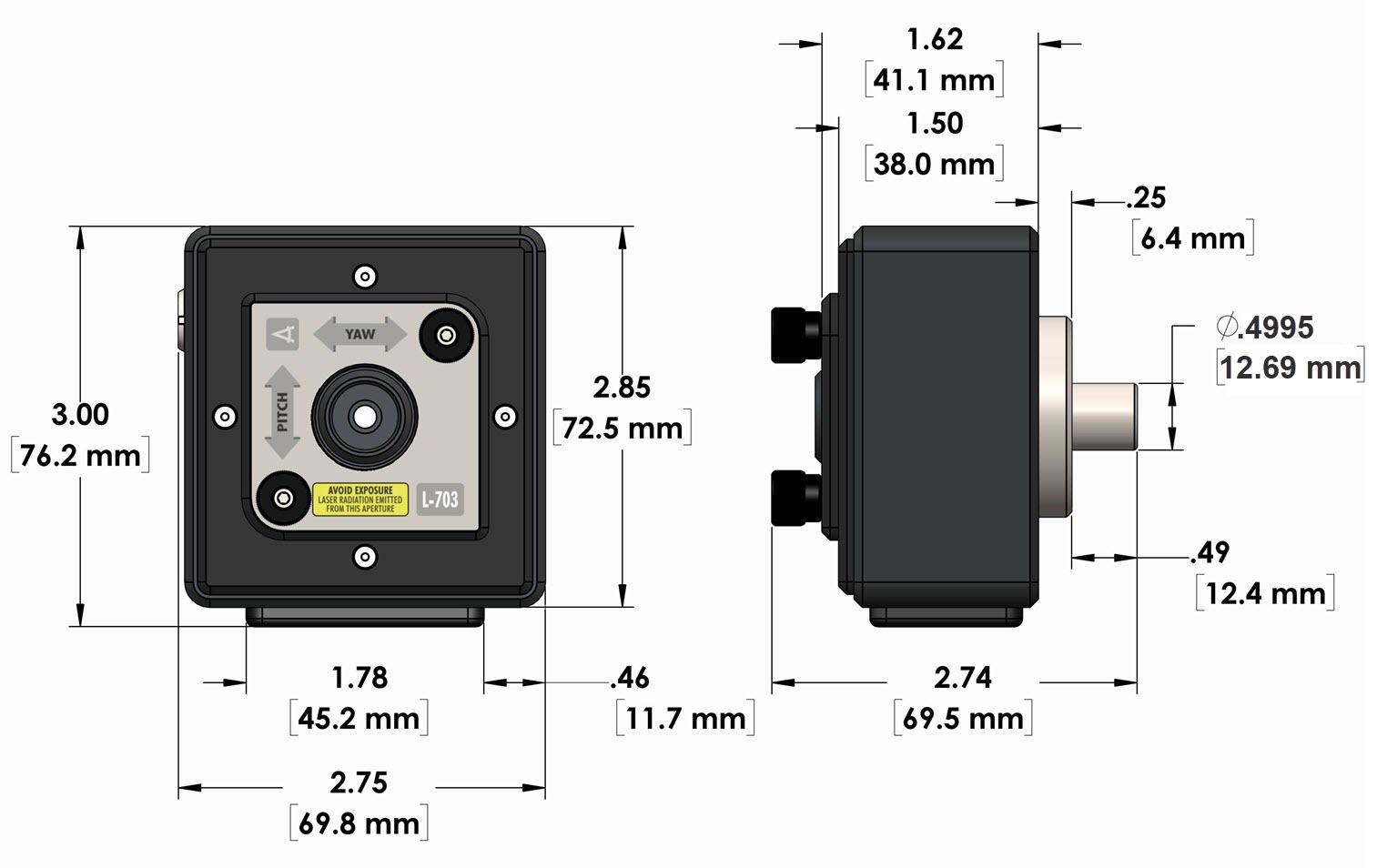

The L-703S features X-Y angular adjustments with a resolution of .00001 in/ft (0.0008 mm/m) and a range of ±0.36° (±.075 in/ft or ± 6.26 mm/m). There is a 0.4995 (12.69 mm) mounting stud with the laser pre-aligned concentric to the stud to <.0005 in. (0.012 mm). This concentricity error is typically eliminated by using either the NORMIN procedure in Lathe10 Software or the L-103 Optical Beam Translator. The L-703S also features a lithium-ion rechargeable battery with up to 14+ hours of battery life. The AC charging adapter can also be used for continuous operation.

The L-703S can be used with any of our spindle alignment targets such as the T-1294, T-1295, T-1296, T-1297 and T-261 and our Lathe10 Software.

Applications

- Guideway straightness checks during PMs and assembly

- Headstock to tailstock alignment for lathes, OD grinders, turning centers and similar machines

- Headstock to guideway alignment for lathes, OD grinders, turning centers and similar machines

- Spindle to subspindle alignments for lathes, OD grinders, turning centers and similar machines

- Surface plate calibration

Features

- Lightweight, portable, Li-Ion battery-operated, compact, rugged design.

- High-resolution angular adjustments for quick alignment of laser beam to bore reference with resolution of .00001 in/ft (0.0008 mm/m) and a range of ± .0375 in./ft (± 3.13 mm/m).

- Long-range, high accuracy can be used up to 50 feet (15 m). A long-distance version is available as well.

- Can be used on many different applications.

- Laser is concentric to mounting stud to <.0005 in. (0.012 mm). This concentricity error is typically eliminated by using either the NORMIN procedure in Lathe10 Software or the L-103 Optical Beam Translator.

- Visible laser beam with collimated 3 mm beam.

- Virtually instantaneous warm-up.

- 14+ hours battery life continuous use.

- Easy fixturing for custom applications.

- Supports most of our spindle targets: T-1294, T-1295, T-1296, T-1297 and T-261 (with R-358).

Specifications

Drawings

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com