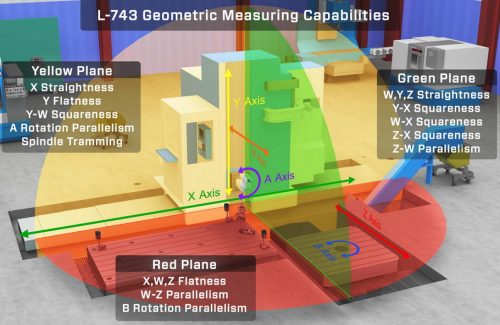

The product of more than 50 years of machine-tool alignment experience, Hamar Laser’s L-743 Ultra-Precision Triple Scan® Laser Alignment System is the ideal tool to quickly and accurately calibrate the geometry of CNC machining centers, boring mills, gantries, CNC floor mills, surface grinders and VTL’s. The L-743 Features:

- 3 automatically rotating laser planes that minimizes setups and speeds up alignments up to 70% faster than conventional methods.

- The highest accuracy in the industry

- Flatness/straightness accuracies up to .00003 in/ft (0.0025 mm/m),

- Squareness up to .00006 in/ft (0.005 mm/m).

- Extremely simple to use and easy to set up, the L-743 can usually measure the machine’s 3 main axes at the same time, eliminating the “stack-up” errors that result from using multiple alignment instruments and setups.

- Measures flatness and straightness of each axis plus the squareness between them.

- Easily measures rotary axes for parallelism or squareness to the main axes.

- Pitch, roll and yaw angularity can also be checked.

- Real-time data means the alignment of the rails and columns can be watched as they are adjusted – a big time saver!

- With an operating range of 100 ft (30.5 m) in radius, the geometry of even the largest machines can easily be measured

- Wireless measuring targets (sensors) resolution of up to .00001 in. (0.25 µm) and a measuring range of up to ± .55 in. (± 14 mm) with an accuracy is up to ± .00004 in. (± 0.001 mm).

- Data is sent via XBEE® radio link to a PDA or PC for display and processing.

- Data from multiple targets can be viewed simultaneously to further speed up alignments.

- Powerful Windows-based software, combined with advanced computer interfaces, makes collecting and analyzing alignment data faster and easier.